In the composites industry, many products require some sort of color specification, written or implied. It is important for fabricators to understand the basic elements of color and color control in order to keep clients satisfied.

For shops that mass-produce molded gelcoat finishes, the gelcoat supplier can do color matching. Fabricators may also consult with pigment manufacturers for help with matching in standard gelcoat bases. However, when compounding custom gelcoats or producing short-run products, in-house color matching can be more convenient. In both scenarios, it is important to monitor color of the final product to ensure the product meets customer demands. This column discusses how to match colors in house, specify a color tolerance, and monitor and control color throughout a project’s manufacturing period.

In-House Color Matching

Matching a client sample in house may seem daunting, but it can be done easily with a basic knowledge of color theory and a little practice. (While color theory is beyond the scope of this column, it can be learned from numerous online or print resources.) Gelcoat suppliers have color software that can calculate a pigment formula based on a measured color. Fabricators typically don’t have access to this software, and have to match by trial and error. A visual match can usually be attained within two to three rounds of color chip samples.

A good matching technique is to start with pigment pastes, which allow you to spend as much time as needed changing and shifting the color. Arriving at the correct pigment color is much like mixing primary colors of paint, except that it is critical to take careful weight records and notes after each addition or subtraction from the mixture. Samples of the pigment paste mixture can be taken to make samples at any time during the process to get a broader range of color options.

Once the pigment paste is close to the desired color, it is then added to the gelcoat base and cured to create a sample. Pigment loading amounts can vary based on color and pigment type, and the gelcoat supplier should be consulted for the proper loading amount.

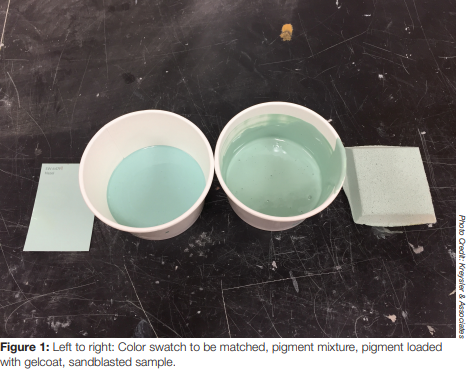

Color shifts due to gelcoat base and processing are important to consider. Figure 1 shows the color shifts associated with a custom gelcoat mixture. The pigment mixture is cooler in hue and more saturated than the swatch to be matched. Once added to the gelcoat base, the color becomes warmer and slightly duller. Final processing for this color was a sandblast finish, which lightens the value and de-saturates the wet color. The final sample is close to the swatch but still a little too warm, requiring another round of matching.

When evaluating a round of color matching, it is important to consider metamerism, a phenomenon in which certain colors can match under one light source but not under another. To avoid issues with metamerism, it is important to evaluate matches under a controlled light source that mimics the lighting the final product will be evaluated under. A color meter can confirm a color match, but never underestimate the human eye, which can also discern very minor color shifts.