Rising 30 feet into the air, a GFRP and CFRP lattice tower built for the architectural showcase Exhibit Columbus in Columbus, Ind., is the first coreless wound filament tower in North America and one of the tallest example of coreless filament winding ever constructed. The tower, which is modeled after the open lattice structure of the cholla cactus, is the brainchild of Marshall Prado, assistant professor of design and structural technology at the University of Tennessee, Knoxville (UTK).

While this is his first tower, Prado previously used coreless winding systems to build domes, cantilevers and other structures as part of his doctoral research at University of Stuttgart’s Institute for Computational Design and Construction. Prado believes that adaptive, moldless technology is key to expanding the use of composites in architecture. “It’s very difficult to build a mold on an architectural scale, for instance the size of a building,” he says. “[Molds] are very suitable for engineering applications, like aerospace or automotive, where they make the same part over and over again. But in our case, buildings are rarely made more than once.”

The goal of the project was to explore computational design and robotic fabrication of composite structures for architectural applications, highlighting the aesthetic qualities of carbon and glass fiber. The tower is composed of 30 unique parts – three CFRP bases that form the foundation, and 27 GFRP and CFRP tubular lattice tower parts ranging from three to eight feet in length with a diameter up to two feet.

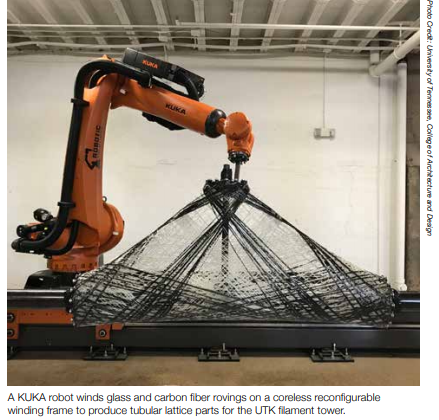

The tubular parts were made in the Fab Lab at UTK’s College of Architecture and Design using robotic fabrication and a reconfigurable coreless frame. The winding frame features a 10-foot long, 4-inch diameter steel pipe mounted on a rotating horizontal axis with 2-inch diameter steel pipe “arms.” Each arm is capped with a circular end plate that has 12 to 16 protruding bolts that serve as winding points. To wind the fibers, the horizontal pipe rotates like a giant rotisserie, while a 9-axis KUKA robot repeatedly pulls one to six glass rovings or 50K carbon fiber tows through an epoxy resin bath, loops them over one arm’s endplate bolt, then moves to another arm and loops the filament over one of its winding points.

For the filament tower, the winding point arms were repositioned for every component, changing their distance, angle and orientation to the main axis. This enabled the creation of unique parts. “Every single part that was made for the tower had a different geometry, so we needed something that could be adjustable and flexible for each component,” says Alex Stiles, a graduate student in energy science and engineering at the university’s Bredesen Center for Interdisciplinary Research and Graduate Education.

Each component also required a unique winding pattern, which presented a challenge. Prado says that creating a winding syntax that could be adaptable to each of the 27 geometries took a lot of time, careful thought and manual calculations before it was completed. The winding syntax also controlled the fiber composition – glass filaments overlaid with carbon fiber filaments in areas that needed reinforcement. “So, the black and white overlay of the two fibers is really mapping the structural performance of the components,” says Prado.