There is a lot of lip service paid to the importance of customer service. But leaders in the composites industry do more than talk the talk. They adopt a customer-centric business model, making clients the focal point of everything they do. This approach not only benefits the customer, but it sets the companies apart, too.

“It’s so important for companies to differentiate themselves, whether they are building a boat or airplane components,” says Megan Multanen, co-CEO of Bestbath. “There is somebody else in the industry doing what you do, and they may have more buying power or more brand name recognition than you. But you can differentiate yourself by focusing on the customer and really taking care of them.”

Any company can become customer-centric, no matter their size or specialty, as is shown in this article by insight shared by three diverse companies: a manufacturer of pultruded products that’s part of a larger group of companies, a family-owned manufacturer of bathing products and a leading distributor of raw materials and processing supplies.

Creative Pultrusions: Solving Problems

“To have a successful business, you need to put customers first. That’s pretty obvious,” says Dustin Troutman, director of marketing and product development for Creative Pultrusions Inc., one of five companies comprising the Creative Composites Group. “But to continue to grow organically, what we do best is partner with our customers and help them solve problems.”

The first step toward a partnership is deciding if a prospective customer is a good match for Creative Pultrusions. “If it’s a simple pultrusion all about price and not performance, then we are not a fit,” says Troutman. “We are a fit when we can use our production and product development engineering solutions to solve problems on a higher end scale.” The manufacturer gathers a wealth of information about potential projects, including the application, performance expectations, budget information and price barriers. If the project is well-suited to Creative Pultrusions’ capabilities and business model, then Troutman says, “We embrace the project 100% and work hand-in-hand with our customer to come up with a solution.”

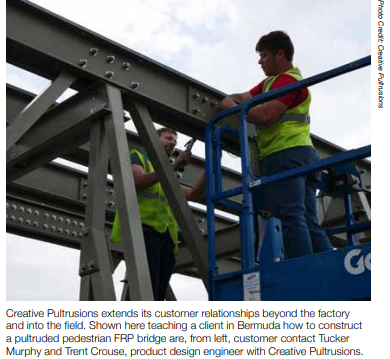

Because composite applications are complex, the company collaborates with clients on technical components of their projects. Creative Pultrusions has three engineers in its structural group to help clients develop specifications for their custom applications. The company has a metrology lab where it can perform most of the standard material characterization tests necessary to develop mechanical properties for GFRP materials. The company also maintains three flexural test units for full-scale component testing and first article validation.

“FRP is a unique material, and you have to understand exactly how you’re applying it,” says Troutman. “We develop characteristic design strengths for our customers and establish the relative mechanical and physical properties so they know exactly how their part will perform.” For instance, Creative Pultrusions designed a pultruded tube for one client, who also asked the company to develop accompanying design and quality standards related to their internal and external requirements. Creative performed three production runs, taking tubes off the production line and testing them to failure, then performing a statistical analysis to help the client draft its structural and quality requirements for the finished product. These requirements then become Creative’s production requirements.

However, Creative Pultrusions isn’t just concerned with product details; it prioritizes customers’ needs all along the sales cycle. “One way we record the voice of the customer – and make sure everybody within our company understands the voice of the customer – is by documenting it in our advanced quality planning (AQP) system,” says Troutman. “All relative personnel has access to the AQP and can pull it up whenever they have a question.”

At the beginning of each project, company representatives meet with the client and document every pertinent detail in the AQP system. In addition to design and manufacturing requirements, the system includes agreed-upon steps the company and customer will take if mishaps happen during delivery, a product sometimes gets scuffed or it needs to be repaired. “We try to prepare for all this upfront because it’s not a matter of if, but when something is going to get damaged during transit. We know upfront, based on the degree of damage, if the product will get discarded or repaired and how it will get repaired. ” says Troutman.

Another testament to the company’s commitment to customers is its tooling policy. “Whenever a client buys a pultrusion die from us, they invest in tooling for life,” says Troutman. “If the die wears out, we build a new one on our dime.”

Troutman cites one defining characteristic in Creative Pultrusions’ quest to put customers first – transparency. “Be transparent with both the positive and negative attributes of composites and how they behave,” he says. “Engineers want to design based on the positive attributes, but more importantly they want to know what can go wrong and how to overcome it during the design phase.”

The same principle holds true when a problem occurs. “People will respect you more if you pick up the phone and say, ‘We have a problem.’ When you do, you can show your customer how good you are at solving that problem and making things right,” says Troutman.

Bestbath: Listening Closely

Multanen says Bestbath’s customers are their No. 1 resource. “We think we know how to solve our customers’ issues, but the reality is it’s the general contractors and architects who are truly dealing with funky drain locations, interesting plumbing or local codes,” she says. “They tell us about their unique needs, then we can provide solutions for those issues.”

The job of listening to customers – truly listening – begins with the sales force. Bestbath has 27 employees in its sales department, 13 of whom are outside sales representatives. As employees of the company, rather than contracted salespeople, they have a vested interest in building relationships with customers. “Our sales reps connect with customers in a powerful way, and they are connected back to the company at large,” says Multanen. “They have the time, the directive and the desire to ask their customers important questions. And they have the time, directive and desire to pass that information back to us.”