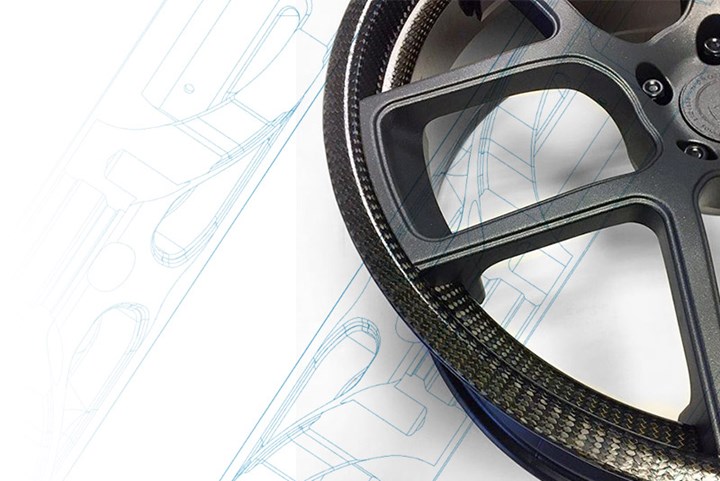

Carbon Fiber Forged Wheels Can Be Produced in High Volume at Competitive Prices

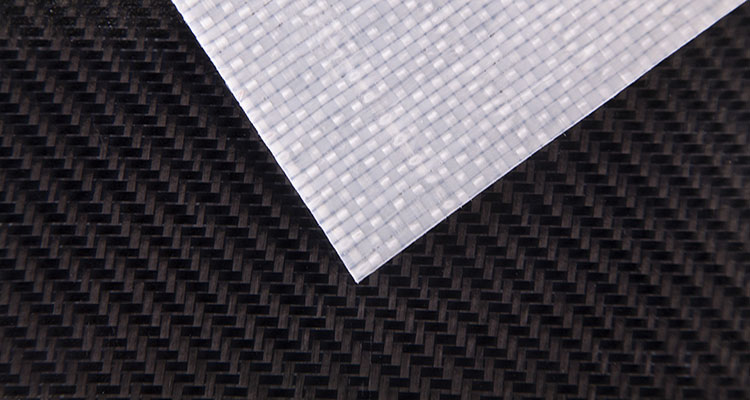

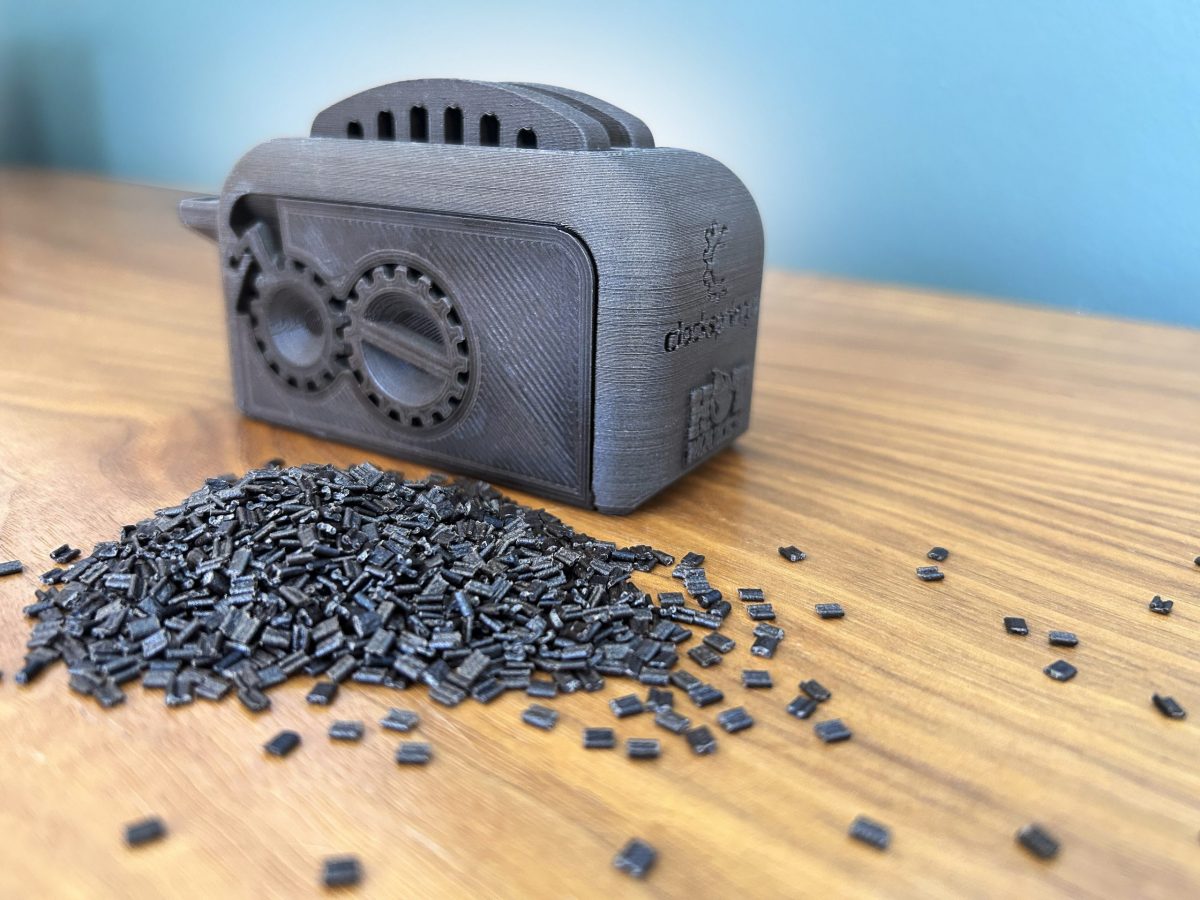

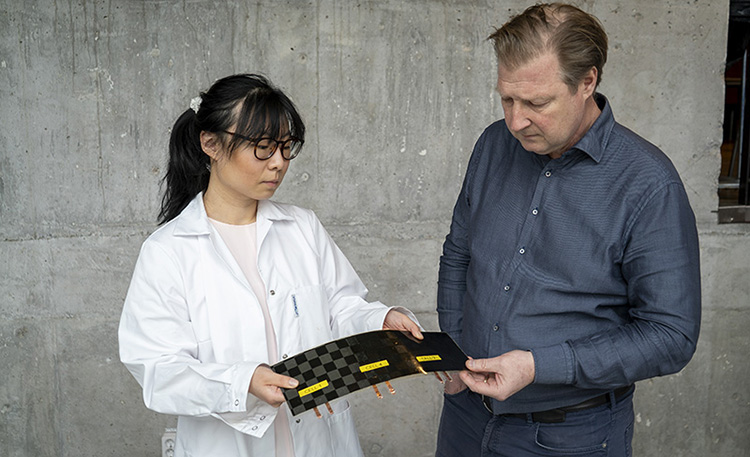

Vision Composite Products selected IDI Composites’ Ultrium™ U660 for its carbon fiber forged wheels.

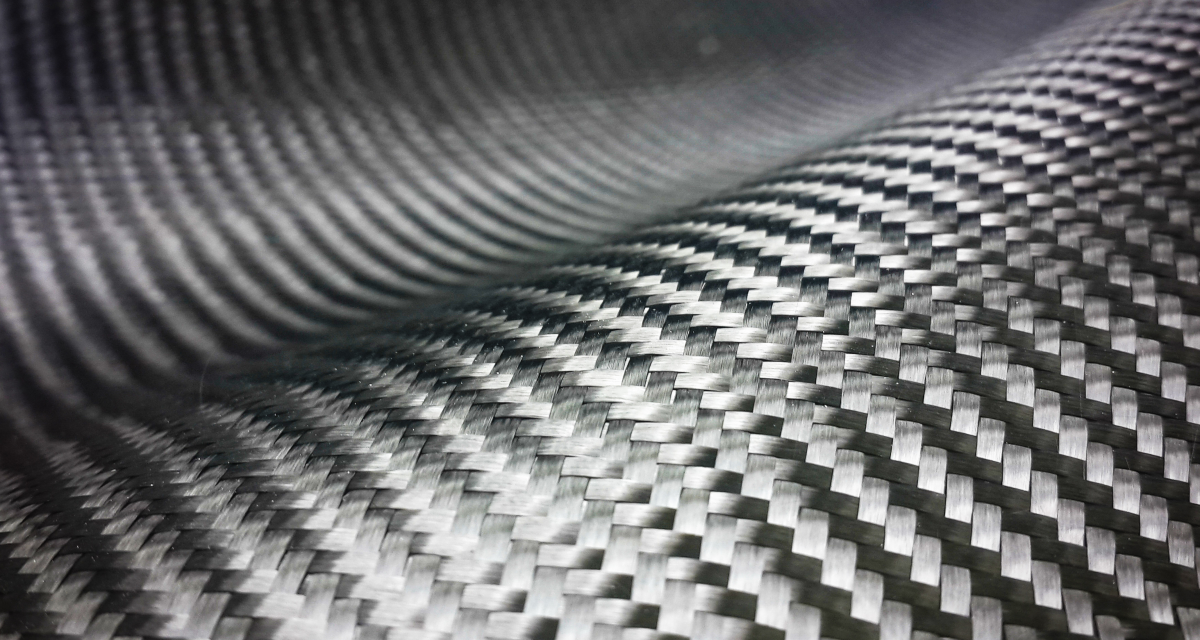

In order to survive harsh conditions, corrosion, and road hazards, automotive aftermarket wheels need to be strong and durable. To enhance drivability with speed, acceleration, and safe stopping time, as well as to help with fuel efficiency, the wheels need to be lightweight. And to appeal to the consumer’s eye, the wheels must be sporty. This is a tall order, and Vision Composite Products (Vision) partnered with IDI Composites (IDI) to use IDI’s Ultrium™ U660 carbon fiber composites to develop high-performance Carbon Fiber Forged (CFF) wheels to meet these diverse needs.

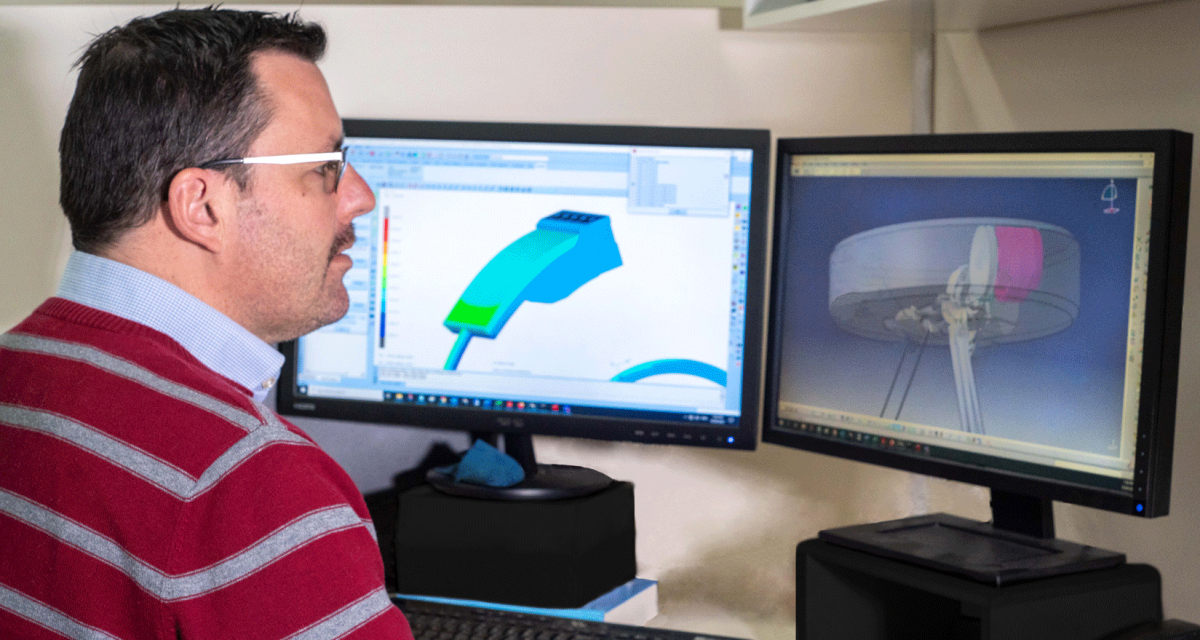

Engineers at Vision researched materials for design of a wheel that would outperform traditional performance wheels cast and forged with aluminum alloy and decided upon composite materials as the solution. To create the new CFF wheels, the team partnered with IDI and the 3i Technology Center. By using Ultrium™ carbon fiber composites, and A&P Technology’s continuous Netshape® preforms in a carbon fiber forged molding process, high-volume production is attainable at a cost competitive to the forged aluminum production process. The new wheel is up to 30% lighter than forged aluminum wheels.

Testing was extensive on the new CFF wheels, and the wheels passed SAE/DOT lifecycle testing by three to five times the standard requirements.

"Ultrium™ is the ideal material for Vision’s new Carbon Fiber Forged wheels," explained Kevin Cahill, director of composite technology for IDI Composites. "Ultrium™ is extremely lightweight and durable, with a beautiful appearance that has the ability to withstand extreme loads experienced on high performance vehicles. This material ensures that these wheels will not only perform well, but the moldability of thermoset composites allows for cost optimized and innovative design options."

"Our 3i Composites Technology Center is truly an asset that helps make projects like these possible." said Tom Flood, vice president and general manager of IDI Composites International. “The 3i Technology Center's testing capabilities and dedicated team of composite chemists and engineers allows IDI to drive innovation and push the performance boundaries of composites beyond the value limitations of conventional materials."

Vectorply combines highly engineered composite reinforcements with industry-leading engineering and technical support to give customers a clear path to achieve their production goals.

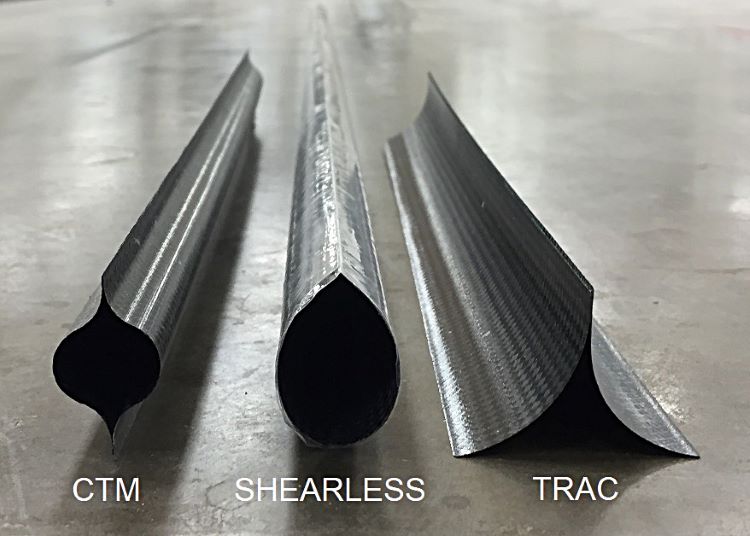

A lower-cost “print only” line of machines built around proven LSAM technology

More from Composites Magazine

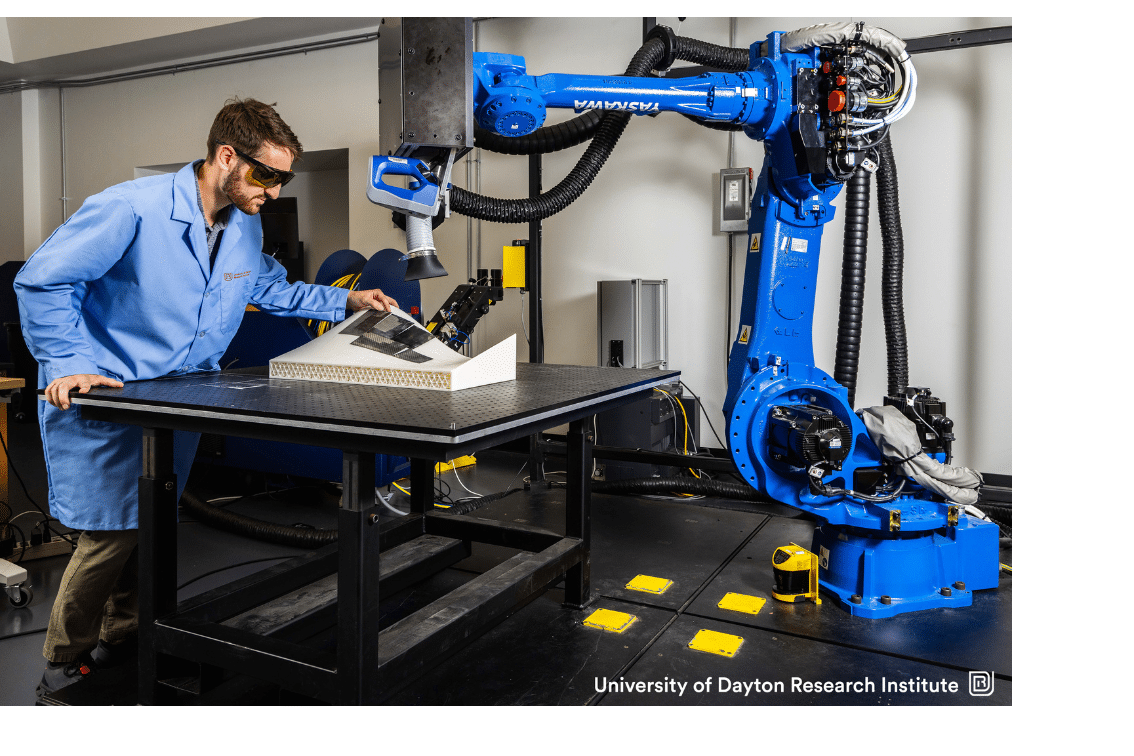

UDRI Engineers Introduced RoboCLASP to Revolutionize Prep of Composite Materials for Bonding

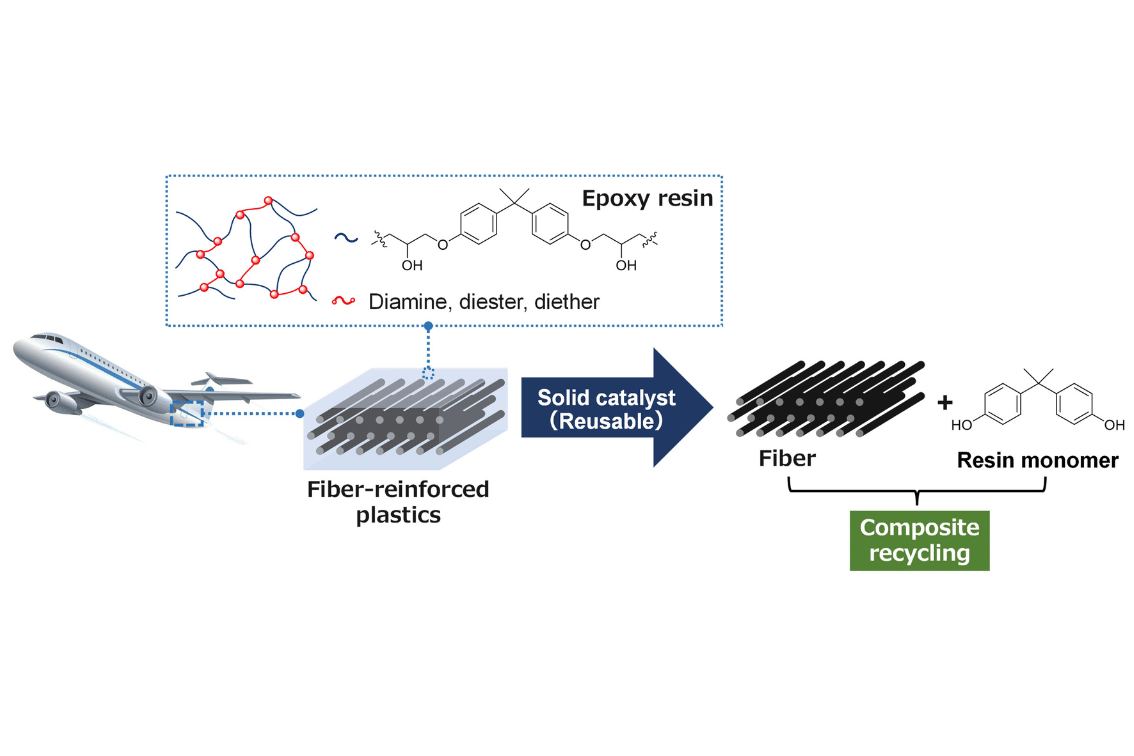

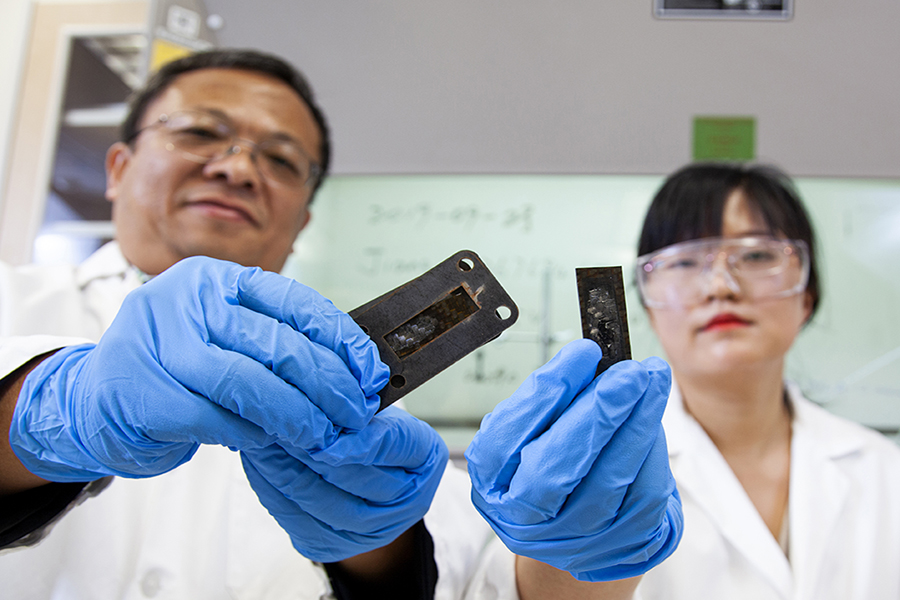

Scientists Developed a Process to Reclaim Composite Materials from Epoxies

Evertrak and Sumitomo Partnering on Sustainable Composite Railroad Ties

Collier Aerospace’s HyperX Software Enhanced Nose Cone of Swift’s X-59 Aircraft

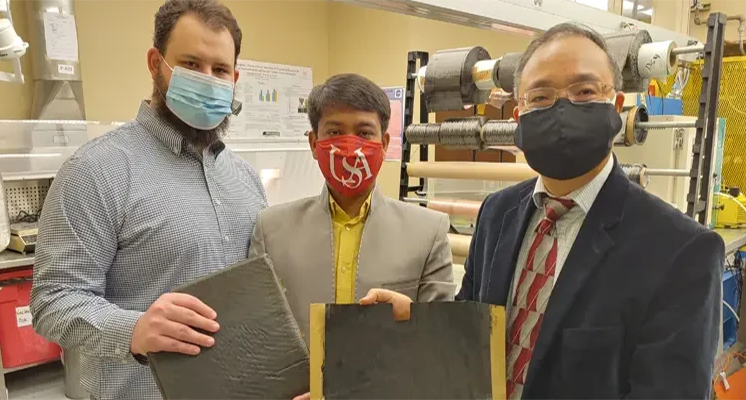

Researchers at USC Are Turning Waste Composite Materials into Usable Fibers and Much More

Decommissioned Wind Blades Are Visual Focus of New Parking Garage in Sweden

Rocket Lab’s Composite Neutron Medium Payload Rocket Clears Another Milestone Towards Launch

Composites Make the Genny Zero Self-Balancing Personal Transporter Lightweight and Strong

ZEBRA Project Developed Closed-loop Recycling Process for Wind Turbine Blades

The PAL-V Liberty completed its first Periodic Technical Inspection (PTI)

RENCO’s Real-life LEGO-like Advanced Composite Blocks Offer a New Way to Build

SABIC Fire-retardant Thermoplastic Battery Module Box Makes EVs Safer

Wabash and Purdue Trailer Supplies Its Own Power from Vibrations

Exel Collaborating with Flying Whales to Design VTOL Cargo Airship

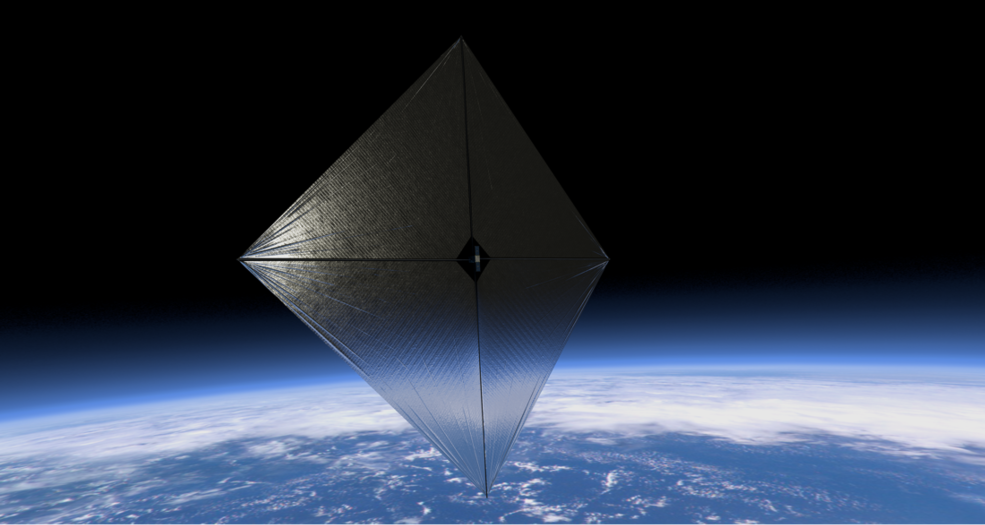

NASA’s Advanced Composite Solar Sail System Ready to Launch

AirX’s AirFish Wing-in-Ground (WIG) Craft is Preparing for Certification

MAN hTGX Zero-emission Small Series Truck Features Hydrogen Combustion Engine

Propeller for Electric Aircraft Offers High Efficiency and Low Noise

3D Printed Honeycombs Could Provide Improved Protection in Football Helmets and More

REIN4CED and DIEFFENBACHER Developed Large-scale Series Production of Thermoplastic Carbon Bicycle Frames

KraussMaffei Created a Biologically Reinforced Bioplastic Incorporating Lignin

Piasecki Developing VTOL Unmanned Aerial Aircraft for U.S. Air Force AFWERX Program

NASA Testing Carbon Fiber Rotor Blades for Mars Helicopters

Inspired Overland Develops Ultra-lightweight Rooftop Tent with Carbon Fiber

Carbon Fiber Being Recycled in Unique Way to Build Superbike

Apply Carbon Commissioned the World’s First Fully Automated Mass Production Plant for Recycled Carbon Fiber

Omni Tanker and UNSW are Leading a Digital Transformation in Composites Manufacturing

Classic Recreations Used Carbon Fiber to Design the 60th Anniversary Shelby Cobra Race Car

Recyclable Turbine for Aircraft Cooling Systems Developed Using Injection Technology

Creative Composites Group’s FRP Panels Used in Restoration of Historic Bridge

Fiberon Wildwood Composite Cladding Features Both Sustainable Materials and Manufacturing Processes

Recyclable FusionFiber® Material Provides Stable Ride in Bicycle Wheelset

Alaska Airlines and ZeroAvia are Partnering on a Hydrogen-electric Propulsion System

NCC and UK Atomic Energy Authority Developing Fusion-grade Silicon Carbide Ceramic Matrix Composites

KU Researchers and Partners Developing Fiber-reinforced Polymers to Reinforce Dams and Levees

Kaebon Carbon Fiber Electric Boat Offers Power and Sustainability

Composite Body Kits Used to Recreate Classic Citroën Van

STUNNING Project Delivers of One of the World’s Largest Thermoplastic Aerostructures

New Low Carbon, Graphene-based Insulation Materials Created for Transportation Industry

DIFT and Arburg Are Manufacturing Bio-based Fiber Composites Using 3D Printing

HAZE’s Carbon Fiber Auto Frame Features AWOS Submersion Sensing Technology

Composite Materials Lightweight the Ebusco 3.0 18 Electric City Bus

Innovation, Collaboration and Sustainability Took Center Stage at CAMX 2022

Airbus Zephyr Drone Sets Record for Uncrewed Flight Duration

UMaine Constructing a Prototype House of Affordable 3D-printed Sustainable Composite Materials

Evari 856 Commuter E-bike is Lightweight and Sturdy Thanks to Carbon Fiber Frame

Butterfly eVTOL Prototype is Utilizing Toray’s Carbon Fiber and Resin System

Sustainable Composite Materials Used to Build Wild Water Kayak

Carbon Fiber Components Help Improve Energy Consumption on High-speed Trains

Federations and Sports Equipment Suppliers Uniting to Reuse Carbon Fiber Components

Lightweight Mercedes Benz Sets World Record for EV Travel on a Single Charge

Sustainable Surfboards Built of Upcycled Carbon Fiber and Bio-resin

Composite V-tail Installed on MQ-9B SkyGuardian Remotely Piloted Aircraft

Concrete Reinforced with Basalt Fiber Tested for Use in Roadways

New Pickleball Paddles Feature Fiberglass and Carbon Fiber Faces

A One-Person Flying Machine Made of Carbon Fiber is Now Available

Composite Components Being Used to Develop Wave Energy Converters for Barges

World’s First Carbon Fiber Composite Large Launch Vehicle Introduced

3D Printed Composite Materials Developed from Forestry Waste Used in Affordable Rural Housing

New Polymer Binds Silica Sand into Composite Material for Use in Multiple Industries

Carbon Fiber Lattice Cell Towers Enable Sturdy and Cost-effective 5G Rollout

NREL’s Focus on Sustainability Leads to 3D Printing of Thermoplastic Wind Blades

Researchers Using Carbon Fiber to Convert Wastewater to Hydrogen for Electric Vehicles

New Bulletproof Material Made from Sustainable Composite Materials

Fiber-reinforced Composite Materials Used in Load Compartment of Mercedes Benz S-Class

A New IMOCA Boat Will be Built from Declassified Carbon Fiber from Airbus

Composite Materials Used to Design Resto-floats Modeled After Classic Cars

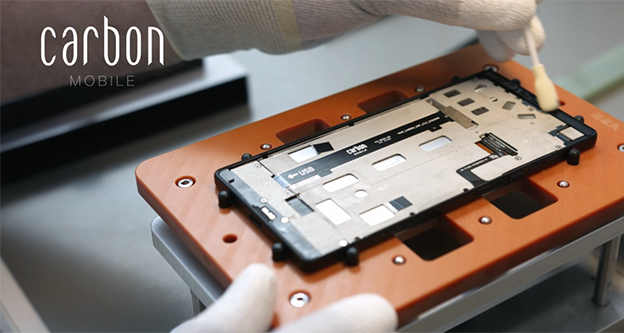

Carbon Mobile Moves Carbon Fiber Smartphone Production to Focus on Sustainability

Introducing RecyclableBlade, the World’s First Recyclable Wind Turbine Blade

Carbon Nanotube Threads Used in Smart Garment to Collect Heart Data

Sewer Lines Restored and Repaired with Carbon Fiber Polymer Lining

New Suit for Formula E Race Drivers Made Safer and Lighter with Composites

Museum Dedicated to Carbon Fiber Being Built of… Carbon Fiber

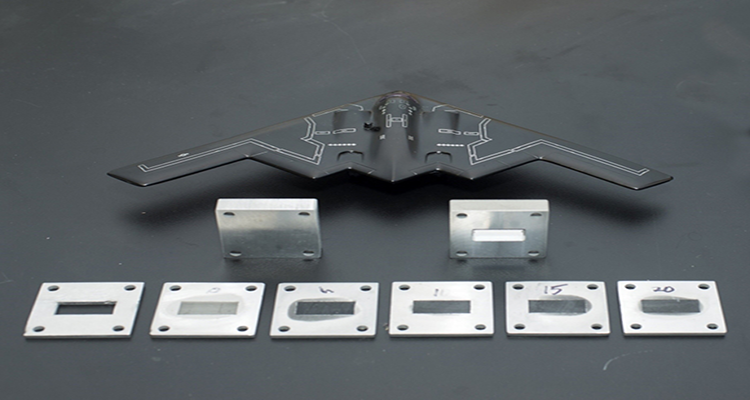

Carbon Fiber Skin Being Developed to Protect Stealth Aircraft

Composite Materials Give Summer Olympians and Paralympians a Competitive Edge

NASA Developing an Advanced Composite Solar Sail System for Future Space Missions

Clean Sky’s SHERLOC Program Using Integrated Sensors to Monitor Composites

Lightweight Motorcycle Helmet Developed with Fiber-Reinforced Composites

Sustainable Composites Used to Manufacture Wheelchair Seat Pan Concept

Lockheed Martin and GM Extending Lunar Exploration with Autonomous Moon Rovers

GE Developing Controls to Support 12 MW Offshore Wind Turbines

Electric Scooter 3D Printed of Continuous Carbon Fiber Thermoplastic Composite

Continuous Composites 3D Printed Power Generator Components for Siemens Energy

New High-performance EV Features a Molded Composite Structural Battery

New Campers Built with Carbon Fiber Install Directly to Source Vehicle

Additive and Composite Manufacturing Wind Blade Technology Applied to Marine Energy Devices

Natural Fiber Composites Used in EVs Participating in Extreme E Championship

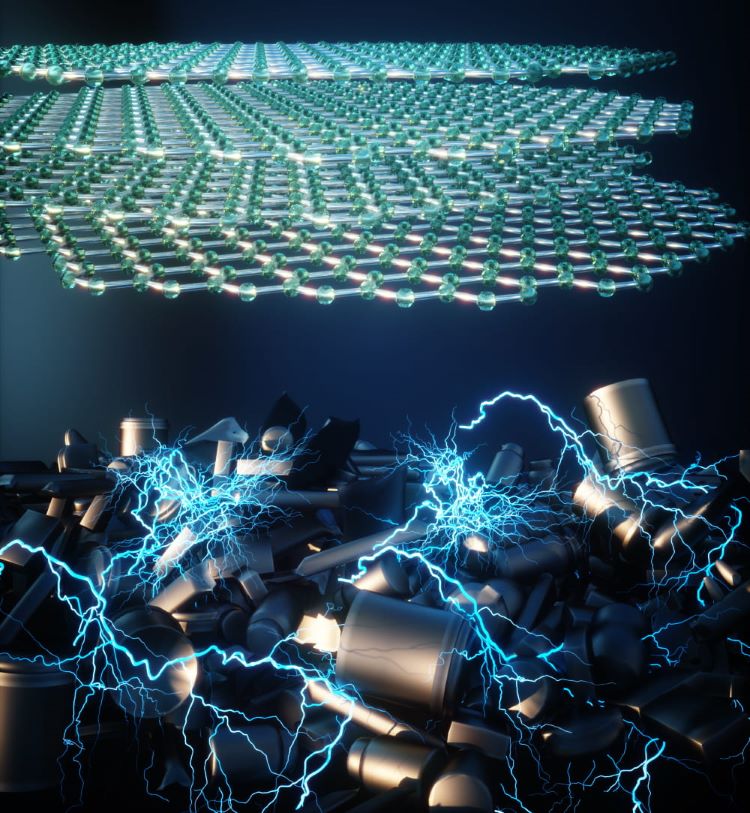

Swedish University Developed Structural Battery with Carbon Fiber Anode

Electric Van Features Composite Body Panels for Lightweighting, Durability, and Cost Savings

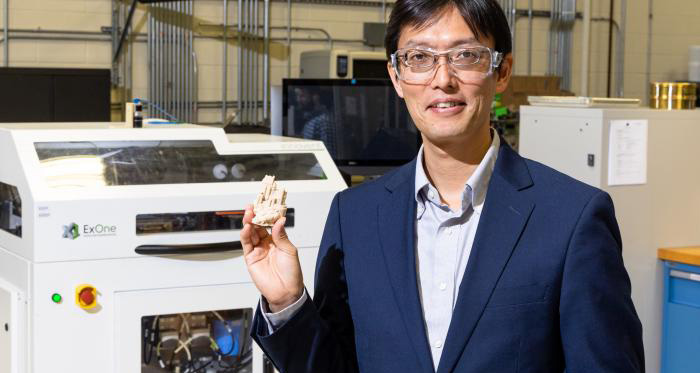

World’s First 3D Printed Zero Net Energy Homes Built with Composite Materials

ZT-CFRP Composite Material Developed with Nanoparticles and Carbon Fiber Reinforcements

New Optimized Method Developed for Recycling CFRP Composites

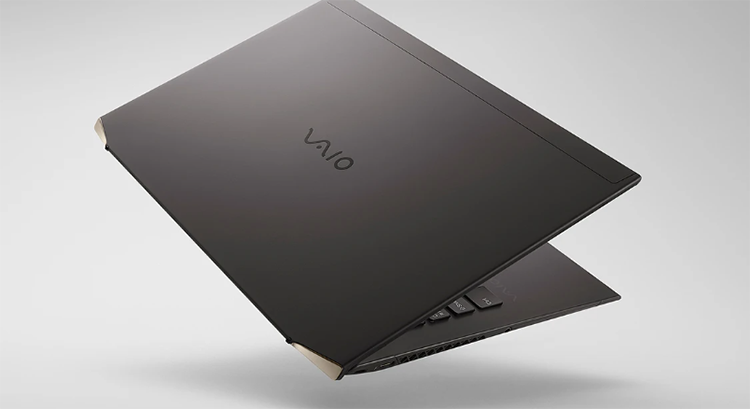

VAIO Introduces the World’s First Contoured Carbon-Fiber Laptop

New McLaren Carbon Fibre Lightweight Architecture Platform Used to Build Artura

SABIC’s LNP™ COLORCOMP™ Compound Enhances Sandwich Structures in Wind Turbine Blades

America’s First Permitted 3D Printed Home is Now For Sale

Composite Deck Boards Offers Natural Looking Surfaces With New Features

Speedkore’s 1970 Dodge Charger Hellraiser Features Exposed Carbon Fiber Body

Carbon ThreeSixty, Leonardo and National Composites Centre Collaborate on New Composite Helicopter Wheel

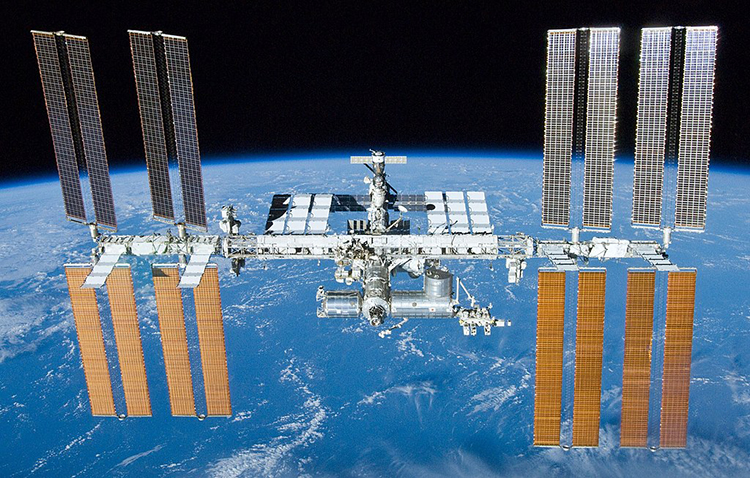

With NASA’s HUNCH Program Students Develop Composite Components for International Space Station

New LeMond ebike Features Carbon Fiber from Handlebars to Fender

Toyota Tacoma Redesigned into All-Terrain Expedition Vehicle with Carbon Fiber Monocoque

High-Tech Roads Include Solar Panels to Fuel EV Charging Stations

Lightweight Distributed Propulsion Hybrid Aircraft Moves Closer to Take-Off

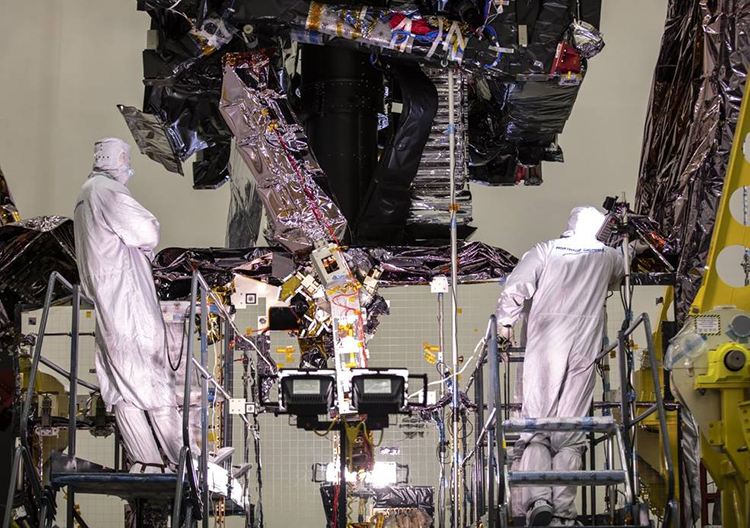

NASA Telescope’s Deployable Tower Assembly Passes Post-Environmental Testing

Service Ramps for Disabled Trolley Riders Made Safer with Composites

Carbon Fiber Windsurf Fins Built with Bio-based Resin Epoxy

Carbon Fiber Composites Used Inside and Out on MANSORY’s Conversion of the Audi RS Q8

NASA Developing New Planetary Construction Technologies with Advanced Materials

Flying Car Designed with Composites Ready to Hit the Road, and Soon, the Sky

America’s Cup Competitor Relies on Composites for Speed and Strength

New All-Electric Car Features Carbon Fiber and Kevlar Interior

MAMBO 3D Printed Boat Made with Continuous Fiberglass Thermoset Material

Luxury 5-seat Helicopter Features High Performance Composite Fuselage

New Technology for Large-Scale Recycling of Composite Wind Blades

Cummins, ORNL Carbon Fiber Technology Facility Collaborate to Produce Face Masks

Bio-Based Dyneema® Fabric Keeps Cyclists Safe in Tour de France

Fire-Resistant Nanocomposite Material Developed for Use in Aircraft Interiors

McLaren’s Formula One Car Features Natural Fiber Composite Seat

BMW Motorrad’s Latest Patent Introduces a Motorcycle with an Innovative Carbon Fiber Chassis

Teijin High-Performance Fiber Strengthens NASA Mars Rover Landing Parachute

Delivery Truck Being Designed of Sustainable Natural Woven Composites

Diamond Aircraft Introduced the DA50 RG, an All Carbon Fiber Airplane

Aston Martin AMB 001 Carbon Fiber Motorcycle Undergoing Prototype Testing

Electric Rigid Inflatable Boat Built with Sustainable Composite Materials

Carbon Fiber Exoskeleton Protects Workers and Boosts Productivity

Carbonhaus is the World’s First Building Made of Carbon Fiber Reinforced Concrete

Eeyo 1 Ebike for City Riders Made Light and Nimble with Composite Materials

Iconic 1967 Shelby Being Recreated with a Carbon Fiber Body

Carbon Fiber Provides Rooftop Camper Sturdiness While Maintaining Light Weight

Composite Sandwich Panels of Recycled Plastics Used in Refrigerated Delivery Pods

Fiber-reinforced Polymer Sunshades Ideal for San Francisco Office Building Retrofit

Army Developed Multi-Filament Polymer for 3D Printing in the Field

Innovative Carbon Fiber Prepreg Transforms Ultralight Aircraft Design

Innovative Spacesuit Prototype Uses Composites to Help Detect Damage

Composites Strengthen Army Future Attack Reconnaissance Aircraft (FARA) Prototype

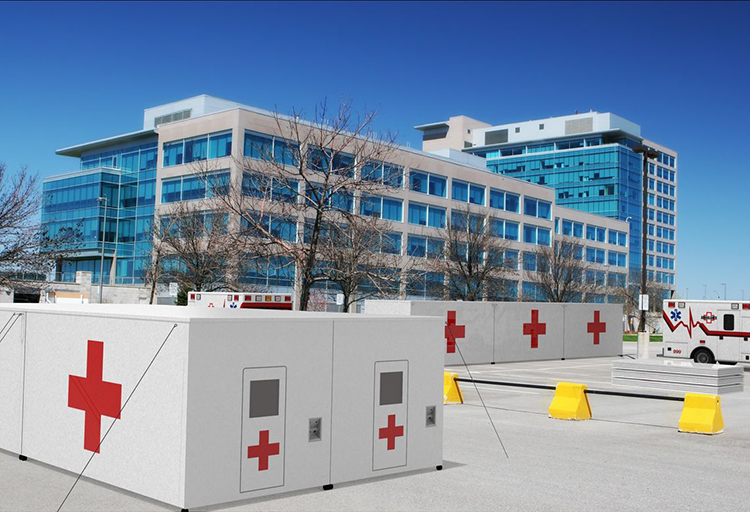

Emergency Medical Shelters Built of Composite Materials are Strong and Quickly Assembled

Composite FRP Being Used to Strengthen Existing Bridges

RUF Rodeo: A Carbon Fiber All-Wheel Drive Safari Rally Concept Car

Alfa Romeo Reintroduces the Giulia with Multiple Composite Components

LOOK’s T20 Track Bike Uses Composites to Be Lightweight, Strong and Ready for Tokyo 2020

Commercial Orbital Rocket Relying on Carbon Fiber and Aluminum Composites to Soar

Omahu Powercat Yacht Constructed of Composite Panels for “Space, Pace and Grace”

Carbon Fiber is Propelling Marathon Runners to the Finish Line

Creating Flash Graphene for Composites from Carbon-Based Waste

NASA Helping Fund Project to Speed Design of Composite Deployable Structures

Lightweight Composite Seat Back Developed for Electric Concept Car

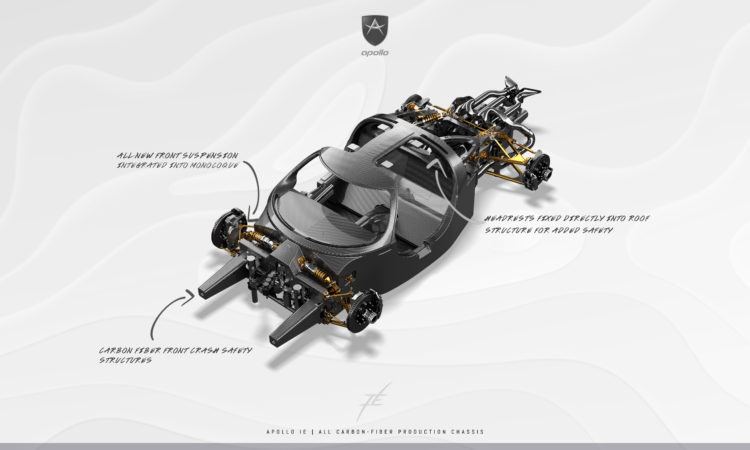

Apollo IE Hyper-Car Uses Carbon Fiber for Strength and Aerodynamics

Composite Aeroshell Will Protect NASA’s 2020 Rover Throughout Journey to Mars

Recycled Carbon Fiber Repurposed into World’s First Carbon Fiber Rail Bogie

Ford and McDonald’s Are Caffeinating Automotive Component Sustainability

FSU Team Develops Carbon Nanotube Heat Shield for Superfast Aircraft

Carbon Fiber Bumper Beam is a Highlight on the New 2020 Corvette

Candela 7 Electric Motorboat Applies Carbon Fiber for a Lightweight, Quiet Ride

EarthRoamer LTi Expedition Vehicle Gains Toughness from Carbon Fiber

Scania’s NXT Flexible Use Autonomous Concept Bus is Built of Carbon Fiber

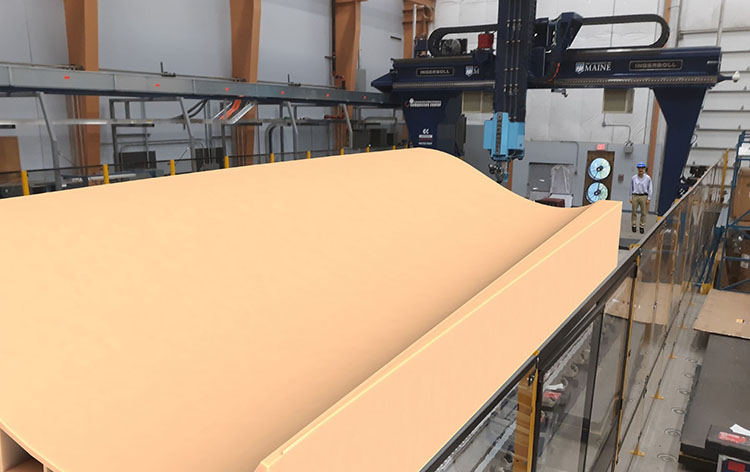

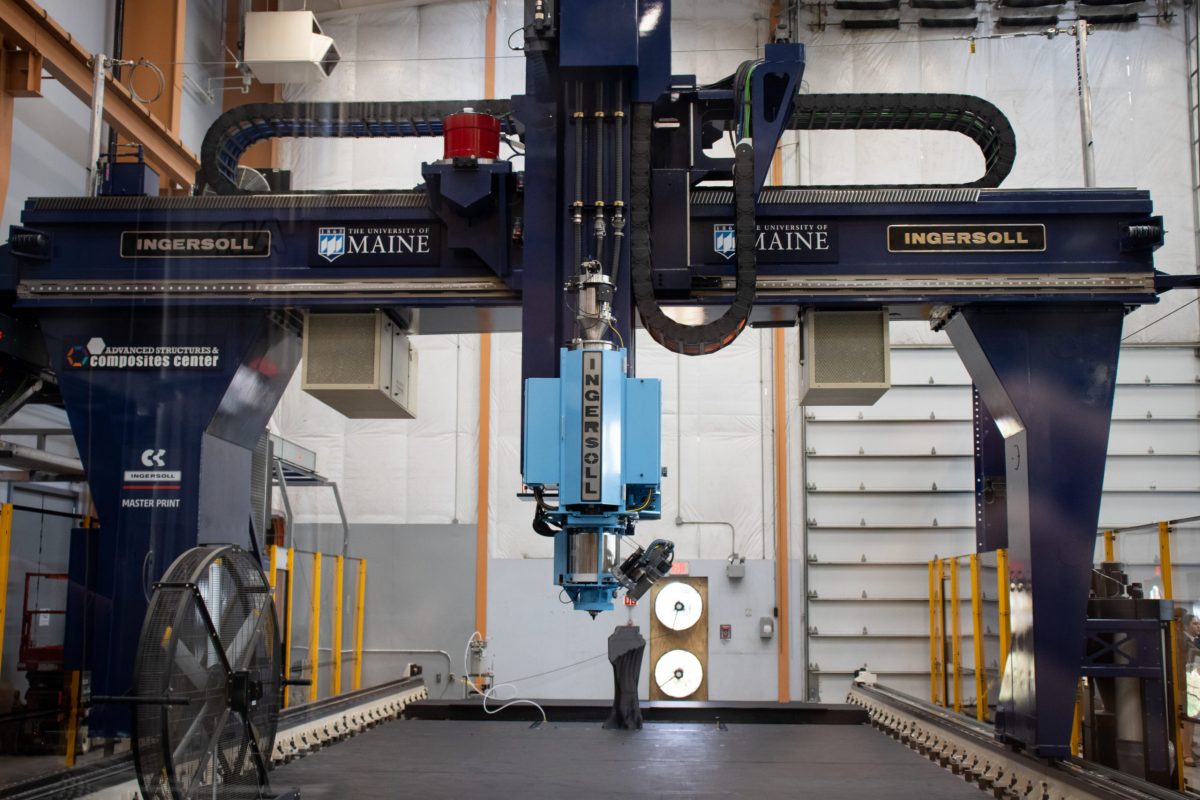

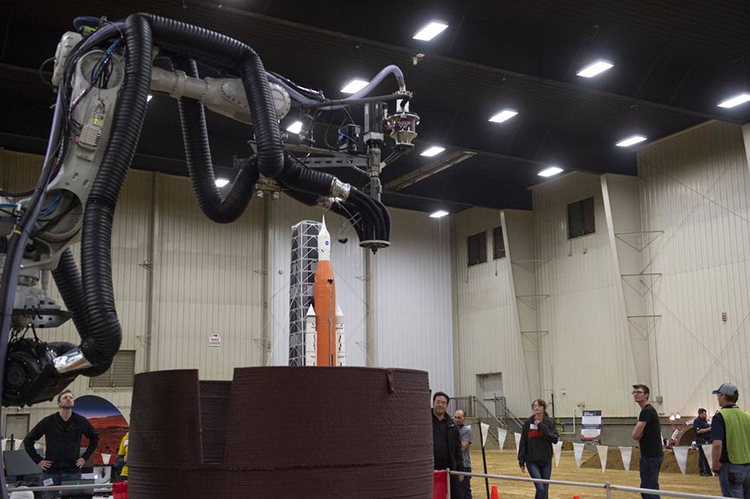

World’s Largest 3D Printer at UMaine Advances Opportunities for Composites

50th Anniversary of Lunar Landing Inspires Motorbike Designer to Use Composites

Lexus LY 650 Yacht Takes Composite Technology and Luxury to Sea

Composites Will be Part of First Hydrogen Fuel Cell Boat in the United States

Rhode Island Marine Industry Moving Forward with Fiberglass Boat Recycling Project

2018 Geneva Motor Show Features European Debuts of New Composite-Intensive Models

Hexion Announces Potentially Groundbreaking “OneShot” Resin Infusion Process for Marine Composites

FastRTM Project Successfully Demonstrates Rapid Manufacturing of Complex, Net Shape, Structural Composites

Owens Corning Forum Highlights Composite Solutions for Sustainable Infrastructure

Composites from Polynt Used in Areas of First Road-Legal Dallara Vehicle

Mobile Solar Solution Featuring Covestro Polyurethane Deployed to Puerto Rico

Premier Composite Technologies is working on the World’s Largest Sliding Dome in Mecca

Arizona DOT strengthens two Interstate 17 bridges in Phoenix with Composites

Hyperloop One Completes World’s First Successful Hyperloop Full Systems Test

Porsche Unveils its Most Powerful, Street-Legal 911 Model Ever

Eviation Aircraft to Develop All-Electric Commuter Aircraft with Composites

KalamSat, The World’s Lightest Satellite Will Show how CFRP Performs in Space

Composite Recycling Technology Center to Reuse CFRP for Park Benches

Model One 3-D Printer from Impossible Objects Could Transform Manufacturing

ACMA Puts Emphasis on Composites in Architecture at AIA 2017

Future Army Soldiers Could Have “Third Arm” to Carry Weapons

Introducing PassivDom: An Autonomous 3-D printed Composite Solar-Powered House

Airbus and Italdesign Unveil Autonomous Flying Car Concept in Geneva

LLNL Researchers Become First to 3-D Print Aerospace-Grade Carbon Fiber

SpaceX Launches Falcon 9 Rocket from Historic NASA Launch Pad

World’s First Flying Vehicles are Being Made with Composites

Researchers are Developing Nanocomposites to Battle Solar Cell Corrosion

Airbus Creates First Single-Piece Composite Center Wing Box

Thermoplastic ICEhouse Stands out at 2017 World Economic Forum

At 216 mph, Ford GT Becomes Fastest Ford Production Vehicle Ever

McLaren and Stratasys Partner to Bring 3-D Printing to Formula 1

Russian Orthodox Cathedral in Paris Features Composite Materials

Sustainable Vehicles among Composite Applications at CES 2017

CES 2017 Features Android Powered “Smart Bike” Made with Composites

World’s First Composite Elevator Unveiled in Singapore

This Electric Personal Watercraft with a Composite Hull is Almost Unsinkable

ORNL’s Massive 3-D Printed Pavilion Wows Crowd at Design Miami

Scientists use Graphene Composites to Make Silly Putty Conduct Electricity

Researchers Create World’s First Reconfigurable Carbon Fiber Robotic Machine Tool

SpaceX Successfully Tests Carbon Fiber Tank for Mars Spaceship

Green Process to Make Carbon Fiber for Rocket Nozzles Receives Patent

Colorado State University Engineers Repair Steel Structures with Composites

MIT and NASA Design ‘Morphing” Aircraft Wings for Efficient Flight

World’s First Biocomposite Footbridge Installed in The Netherlands

NASA Completes Construction of Highly Anticipated James Webb Space Telescope

Cal Poly Students Will Attempt Solar-Power Land Speed Record in 2017

World’s First Four-Seater Hydrogen Fuel Cell Plane Has First Flight

MIT Creates “Foundry” – The Photoshop of Composite 3-D Printing

MIT and Google Create Private Drop-Down Meeting Spaces with Fiberglass

Carbon Fiber Bike Sets World Record for Human-Powered Speed

Teijin Acquires Continental Structural Plastics for $825 Million

Briggs Automotive Company Develops World’s First Car Made with Graphene

New Floating Carbon Fiber House Splits in Two after Divorce

Cyclotron’s Carbon Fiber Bike Rides without Spokes or Wheels

Boeing to Make 777X Components with Composite Material from U.A.E.

Toyota and BMW Working on Next-Generation Supercars with Composites

Oak Ridge National Lab 3D Prints Table with Composite Bamboo Fiber

Spirit AeroSystems Installing One of the World’s Largest Autoclaves for Composite Manufacturing

This Canoe Made with Composites Folds like Origami

British Researchers to Test Carbon Fiber Satellite that Collects Space Debris

Swiss Students Go 0-62 MPH in 1.51 Seconds in Record-Breaking Vehicle

IACMI Partners with World’s First Carbon Fiber Recycling Facility for Product Development

New Lamborghini Composites Center Experimenting with Revolutionary Carbon Fiber

Quebec Students Set North American Fuel Efficiency Record at 3,788 MPG

Local Motors Debuts “Olli” – a Self-Driving 3D-Printed Car

The X-57 – NASA’s First X-Plane in 10 Years – Will Fly Next Year

Solar-Powered Aircraft with Composites Has First Test Flight

Carbon Conversions Recycling Process Featured on Science Channel

Russia Unveils Potential Competitor to Airbus 320 and Boeing 737

Ukrainian Team Designs CO2-Powered Robotic Probe for Mars Exploration

BMW Ramps up Investment in Driverless, Carbon Fiber-Based Electric Vehicles

New Composite Cabin Design Could Revolutionize Passenger Vessels

Rolls-Royce Develops Carbon Fiber Propulsion System for Benetti Mega-Yachts

Airbus Launches ACJ350 XWB: A Wide-Body Version of the A350

Ford GT Becomes Second Ford Vehicle with Carbon Fiber Wheels

EnvisionTEC Unveils First Disruptive Industrial Scale Composite 3D Printer

MIT Students Use Composites to Build Human-Powered Aircraft

Hydrogen Powered Car Made with Composites Debuts at London Auto Show

Futuristic Army Aircraft with Composites Could Replace Black Hawk

Virginia Could Add 5,000 CFRP Jobs Annually Over Next 15 Years

GE Beings Ground Testing for World’s Largest Commercial Aircraft Engine

DARPA Unveils Sea Hunter – A Robotic, Autonomous Warship Featuring Composites

Researchers Creating Flexible Shelter with Robotically Wound CFRP

BASF Helps Produce World’s First Automotive Roof Frame Made with Natural Fiber

New River Thames Bridge Made with Fiber Reinforced Polymer

Inspection Tool for Airbus Composite Airframe in High Demand

Carbon Fiber Composites Protect Japanese Building from Earthquakes

2050 Motors Bulletproof, All-Carbon Fiber Electric Vehicle now in the US

Chicago Cubs Wrigley Field to be Preserved with Composites from DowAksa

Local Motors to Pre-Sell World’s First 3-D Printed Car Series in 2016

FRP-Made San Francisco Museum of Modern Art (SFMOMA) Nears Completion

Ascent Aerospace to Manufacture Largest Wing Skin Molds Ever

Port of Port Angeles Moves Forward on Composite Recycling Technology Center

Miami Students Replace Steel in “Fate Bridge” with GFRP

Air Force Wants Composites to Replace Titanium in Military Aircraft

NASA Creating Biggest Composite Rocket Parts Ever for Mars Mission

Scaled Composites and Microsoft Close to Completing World’s Largest Airplane

Ford Reinvents the Carbon Fiber Wheel for Shelby GT350R Mustang

World’s First 3-D Printed Office Building to be Built in Dubai

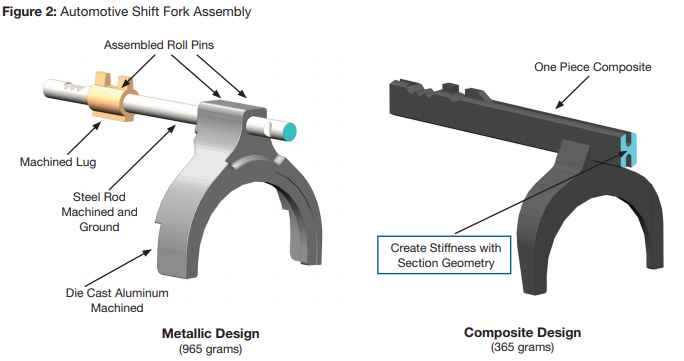

Could Carbon Fiber-Reinforced Gears Really Replace Metal in Cars?

Out-Of-Oven Self-Heating Carbon Nanotubes Heat Aerospace Composites with Less Energy

These Developments Pave the Way for New Subsurface Imaging Techniques for Carbon Nanotubes

Research With Rapier Loom Could Improve Resin Transfer Molding Processes

Composites Hit the Road to Replace Steel in Manhole Covers

This Solution Enables Boat Builders, Designers to Conduct Rapid Feasibility Studies

These Carbon Composites Shape-Shift in Response to Environmental Triggers

Carbon Fiber Makes for More Comfortable Bike Seat

New Composite Trucking Solutions Reduce Weight and Fuel Costs

World’s First CFRP Propeller Installed in Main Propulsion System of a Merchant Vessel

Patterned Surfaces Within Materials Can Provide New Sources of Strength

Google Purchases Titan Aerospace in Efforts to Expand Internet Access

North Carolina Plant Becomes First to Handcraft Engines Using CMC

Danish Startup Creates Carbon Fiber Chassis Without Special Equipment

Can Carbon Fiber Composites Be the Future Material for Shipping Containers?

German Firm Uses 3-D Printing to Create Large Scale Automotive Composites

Lucintel Report Forecasts Composite CNG Tanks Market to Reach $524 Million

Mansory SLR Renovatio by MS Motors, a Tree-based, Renewable Alternative to Fiberglass

Audi Debuts New Plug-In Hybrid at the 2014 Consumer Electronics Show in Las Vegas

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.