A Cure for Aging Pipelines

Early last fall, the E.ON Group, one of Europe’s largest operators of energy infrastructure and networks, discovered a leak in a pipeline under railroad tracks close to the Ӧrebro station in Sweden. Traditional repair of the steel pipe would require digging and redirecting train service on the tracks, which is the main route between Stockholm and Gothenburg, Sweden’s two biggest cities. So E.ON Group opted for a less disruptive alternative – CarboSeal® cured-in-place-pipe liners.

“Changing this section of pipe would have been very challenging, both in terms of time consuming and high costs,” says Clas Hammarlund in distribution and optimization with E.ON Ӧrebro. “By using CarboSeal, we were able to fix it and renew this section without disturbing the train traffic. The work was much faster and far cheaper than the alternatives.”

Made from TeXtreme® spread tow carbon fiber and a custom epoxy resin, CarboSeal liners are designed for district heating pipework. District heating, which is common throughout Europe, uses insulated underground piping networks to provide thermal energy to multiple buildings from a central energy plant. Maintaining heat distribution pipes that carry pressurized water at 110 C is paramount to delivering low carbon energy to communities. Overtime, the steel pipes can deteriorate and leak, necessitating replacement or repair.

CarboSeal offers an alternative to other rehabilitation methods, such as digging up and replacing pipes, steered drilling or directional drilling. Once cured, the liners have the same expansion properties of steel and can withstand pressure greater than 16 bars (one bar equals 100,000 pascals).

“The old steel pipe can fully corrode away, and CarboSeal will be able to take all the loads expected to be borne by the host pipe,” says Andreas Martsman, CEO of PPR, the company that spent more than a decade developing, testing and fine-tuning CarboSeal liners. In 2019, PPR was purchased by Oxeon, which also manufactures TeXtreme materials. The CarboSeal liners were launched commercially in 2021.

When E.ON Ӧrebro detected leaks in a 60-meter-long pipeline section in 2022, executives recalled a meeting with PPR a year earlier when the company introduced its product to the market. The energy company considered steered drilling to replace the pipe, however that technique involves massive excavation pits and large support structures, in addition to interruptions in railroad service. Directional drilling was another option, but it requires significant space behind the equipment to drill into the ground at an angle and pull in replacement piping.

“It is all doable, but at a much higher cost than CFRP liners,” says Martsman. “E.ON Ӧrebro estimated it would’ve been at least three times the cost of CarboSeal.”

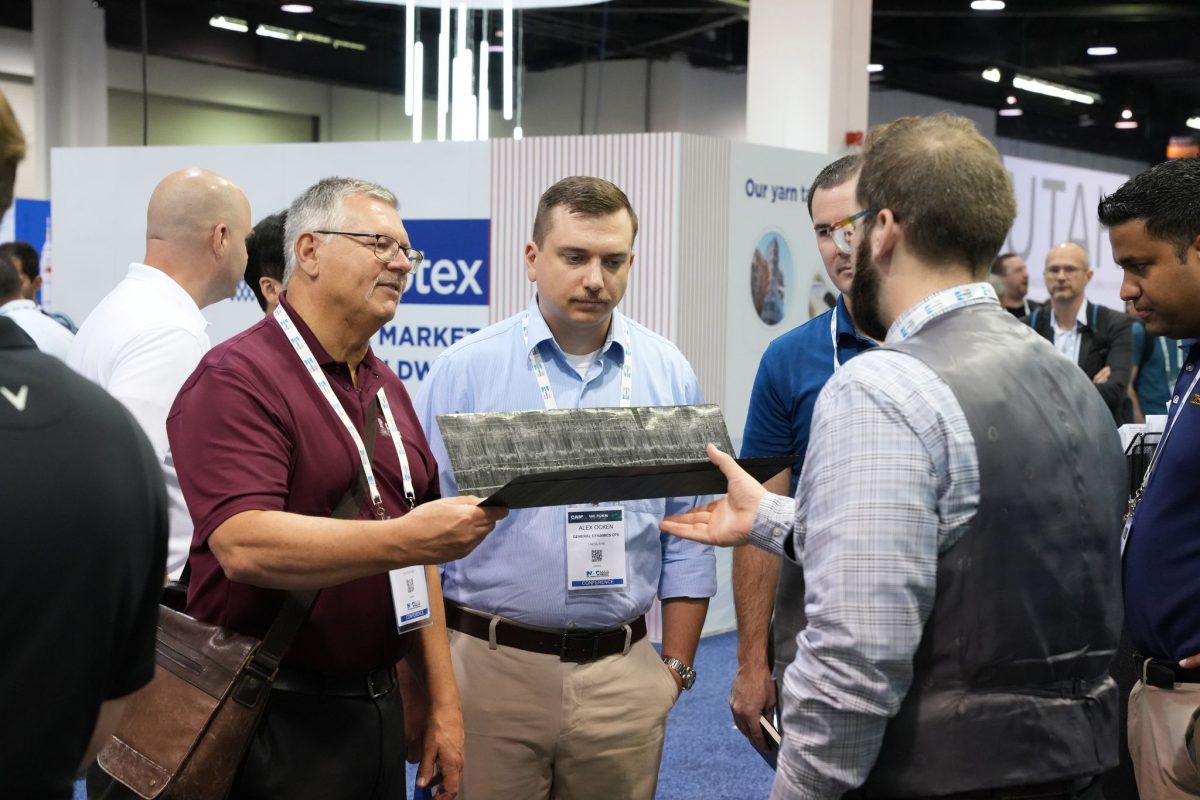

The Ӧrebro pipe repair process involved several steps. First, excavators dug two small pits – one on each side of the railroad tracks – to reach the leaking pipeline. Next, a crew accessed the pipe through existing chambers and emptied the water. Then, the team cleaned the pipe with high-pressurized water and conducted a video inspection to ensure the pipe was fit for relining.

“When we did the video inspection, we found a lot of poorly done welds at the top and bottom of the pipes, so we had to go in and machine them away,” says Martsman.

Afterward, the liner, which arrived at the worksite folded in a box, was ready for installation. The pipe was cut on either side of the damaged section, then the 450-millimeter diameter liner was mounted to an end can and pulled through the pipe. At this point, the liner resembled a long, deflated balloon. The second end can was mounted, both end cans were braced, and the liner was pressurized to 0.2 bar.

A combination of pressure and steam, slowly increasing in temperature, cured the liner for 8 ½ hours. Once the liner was cured, the crew removed the end cans and fit a rubber seal over the end of the liner to ensure that no water can slip between the liner and the host pipe. The entire installation, including both the flow and return pipe, took approximately four days.

Ease of installation is one of the advantages of CarboSeal. Customers can visit PPR to learn the process, then company representatives assist the client with their first installation. While the company provides support on subsequent installations, customers are usually confident in self-installation after one project.

Sustainability is another key benefit of CarboSeal liners. “You don’t dig up old pipes, throw them away and produce new pipes with polyurethane insulation and plastic covering,” says Martsman. “Compared to excavating, the carbon footprint is reduced by about 80%.”

The design life of the cured-in-place-pipe liners is approximately 35 years. While PPR has tested its product’s ability to withstand harsh conditions, the company can’t fully predict longevity.

“It’s hard to speed up long-term testing,” admits Martsman. “The only way we will really know is when we take the liners out of the ground in 40 years and say, ‘Wow, it still looks new.’ But everything is pointing in that direction.”

E.ON Ӧrebro anticipates using cured-in-place-pipe liners for future renovations.

“CarboSeal is a great solution for renewal of district heating pipes in difficult areas and where the conditions are right,” says Hammarlund. “We will have great use of this technique in these problematic areas as we keep upgrading our network.”

Susan Keen Flynn is managing editor of Composites Manufacturing magazine. Email comments to sflynn@keenconcepts.net.

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.