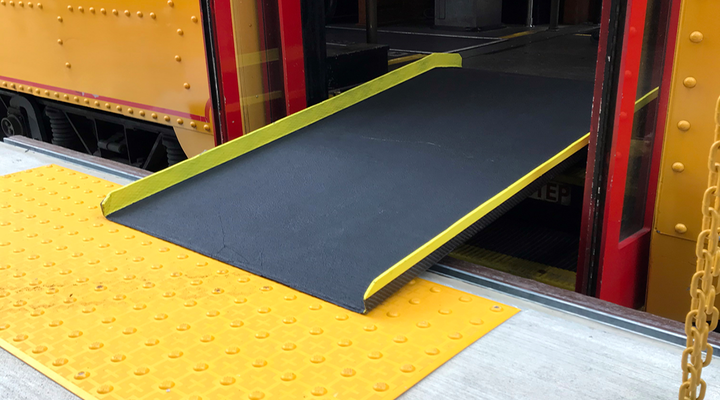

Carbon fiber-reinforced polymer (FRP) is being used to build new service ramps to bridge the gap between the rail trolleys and the station platforms on the Memphis Area Transit Authority’s (MATA) rail trolley cars. It is essential for the safety of the employees and the riders that the ramps be strong and sturdy and also light enough to be placed easily by the trolley operators. The MATA team reports that the new ramps built of composite materials are 60 percent lighter and three times stronger than the traditional metal ramps. Of key importance, the new ramps are ADA (Americans with Disabilities Act) compliant, allowing for secure loading of riders using wheelchairs, walkers, and other assistance devices.

Knowing QuakeWrap’s history of using fiber-reinforced polymers in structural engineering rehabilitation projects, WSP USA, engineering consultants to the MATA Trolley Division, called on QuakeWrap for the design and fabrication of the new ramps. Being able to rehabilitate the infrastructure instead of replacing the entire structure prevented long service interruptions and provided significant cost savings.