A water-soluble novel polymer designed by researchers at Oak Ridge National Laboratory (ORNL) binds silica sand for 3D-printing for molds, prototypes, and part production in industries such as automotive and aviation.

The ORNL team created a polyethyleneimine (PEI) binder that doubled the strength of sand parts compared with conventional binders. Initially porous, binder jet printed parts are strengthened by adding cyanoacrylate to fill gaps, providing eight times the strength when compared to the initial output. The PEI binder is strengthened by the reaction of the polymer to bind with the cyanoacrylate during curing.

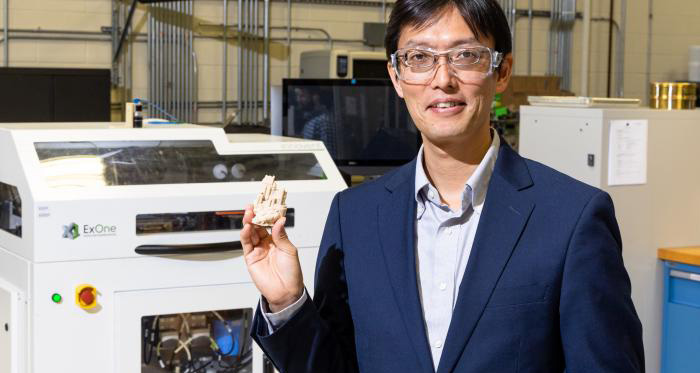

Tomonori Saito, a lead ORNL researcher on this study, explained, “Few polymers are suited to serve as a binder for this application. We were looking for specific properties, such as solubility, that would give us the best result. Our key finding was in the unique molecular structure of our PEI binder that makes it reactive with cyanoacrylate to achieve exceptional strength.”