INCA Renewtech will mass produce BioBalsa at a new 164.000-square-foot hemp processing and composite manufacturing facility in Alberta, Canada, and its other hemp-based composites at a new 235,000-square-foot manufacturing facility in Elkhart County, Ind.

IPCO AB, which has worked on other projects with INCA Renewtech, will design and manufacture the BioBalsa production equipment. Michael Tobiasz, IPCO’s regional product specialist and business development manager for composites in North America, says it will feature a Teflon™ double belt press that will consolidate the materials, heat them and exert the equalized surface pressure necessary for the desired calibration, thickness and densities of the material, and then cool it. The IPCO equipment will be a continuous process machine, capable of producing the long lengths of BioBalsa material that the wind blade industry might require.

The manufacturing line is being designed for maximum production flexibility. “The line is designed right now to run 100 pounds of BioBalsa per minute. That’s a line speed of 10 meters a minute, at 40 inches wide, a half-inch thick and a 10.5-pound density,” says Balthes. “But we can very quickly adjust the layering so that we can make it a 15- or 20-pound density.”

Large-scale production of BioBalsa for wind blades should begin at the factory in early 2024. In the meantime, INCA Renewtech and Gurit will put prototype BioBalsa blades through the independent laboratory testing required to gain widespread market acceptance for the new biocomposite.

David Saltman is optimistic about the future but realizes hurdles remain. “We know with Gurit, we have to be performance competitive, we have to be price competitive, and we have to be manufacturing at volume,” he says. He acknowledges that achieving all that is a lot to accomplish in less than two years.

“The real challenge is that we have to go from zero to 60 in four seconds,” he says. If their efforts are successful, BioBalsa could become an integral part of the wind energy industry before too long.

Mary Lou Jay is a freelance writer based in Timonium, Md. Email comments to mljay@comcast.net.

Prepare for a Sustainable Future

ACMA is committed to sustainability. It has launched a Climate Impact Project to provide essential tools, resources and education to help composites manufacturers assess climate impacts associated with production of their products and raw materials, as well as provide information requested by customers. For more information, visit acmanet.org/acmas-climate-impact-project.

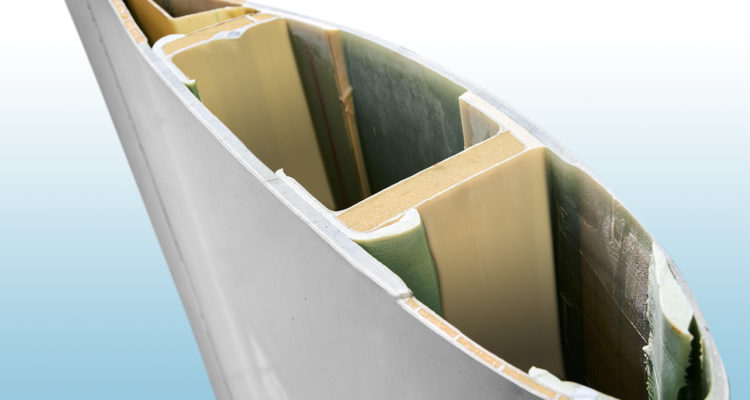

BioBalsa, a composite made with the fibers found in hemp hurd, has the necessary properties to replace the natural balsa wood that provides internal support for giant wind blades.