Glass fiber suppliers are working to recover fiber from end-of-life composite products and reinsert this material into the fiber making process, which will provide reductions in the climate impacts associated with glass fiber.

Recycling companies are also working to recover useful material from glass-fiber reinforced plant scrap, and researchers and some composites manufacturers are investigating the use of natural fiber, like that derived from hemp, as reinforcement in composites.

Carbon fiber production is also associated with the emission of significant quantities of climate warming gases. Several recycling companies offer technologies for recovering carbon fiber from end-of-life composite and plant scrap and processing it for use as a replacement for virgin fiber to make new composite products. This practice has the potential for significant reductions in the climate impacts associated with carbon fiber reinforced composites.

When considering the use of recycled material to replace virgin material, the emission of climate warming gases associated with the collection, transportation and processing of scrap or end-of-life material to prepare usable recyclate must be considered. Collection and transportation are major challenges to establishing a reliable supply chain for recycled composite material.

Manufacturers may find that the reduction of climate impacts associated with generation of process energy is an attractive approach to decarbonization, as this will typically not involve process or raw material changes. Many manufacturers buy electricity generated using renewable sources such as wind or solar, although this usually comes at a higher cost. Some companies install solar panels and use the energy generated directly or sell it to their electric utility.

It’s not too soon for composites manufacturers to start planning for decarbonization. Especially critical at early stages will be bringing suppliers and customers into your planning process.

John Schweitzer is vice president of EH&S and sustainability at ACMA. Email comments to jschweitzer@acmanet.org.

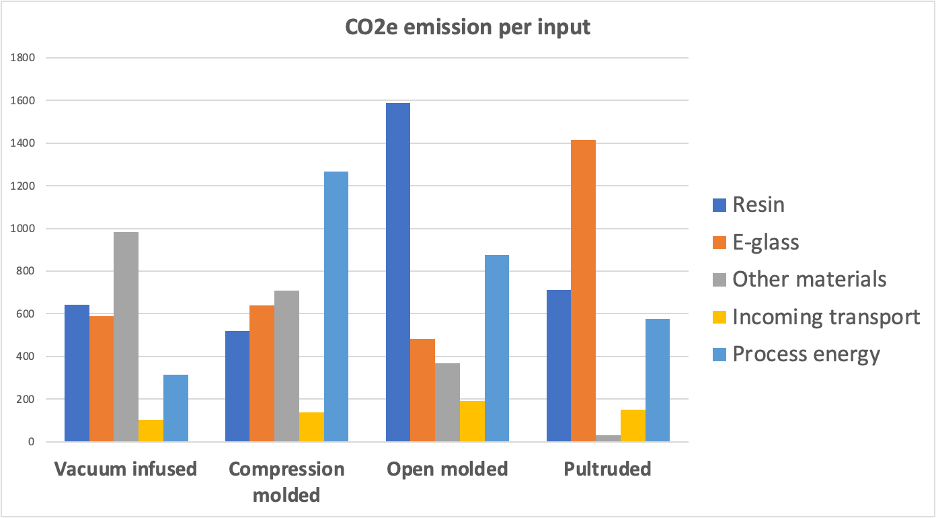

Sources of Climate Impacts Associated with Composites Manufacturing Processes

* CO2e, or carbon dioxide equivalent, describes different greenhouse gases in a common unit.

Note: The figures represent averages across several companies that volunteered to provide data and may not be representative of every operation using each of the process types.