Comparing impacts across materials – On a cradle-to-gate basis, producing 1 kg of steel rebar using recycled steel in a hydroelectric-powered electric arc furnace is associated with emission of less than 1 kg CO2e, while producing the same mass of pultruded composite rebar is associated with the emission of more than 2 kg CO2e per kg product. That doesn’t mean use of steel is more climate friendly. Mass provides a poor basis for comparing the two products as the mass of composite rebar needed to reinforce a concrete deck is much lower. But what is the relevant basis for comparison? Possibly some physical property, such as the degree of bending under load that is related to important properties of the reinforced structure. This is an important question if we are going to successfully compete with other structural materials based on climate impacts. ACMA has commissioned an effort by researchers at West Virginia University to compare climate impacts of composite and steel components in structural applications and assess the utility of various bases of comparison, such as response under load.

Companies that want to compete in sustainability-driven markets will likely need lifecycle analyses for their products. For member companies, ACMA is the source of information, resources and tools for cost effectively preparing the LCAs they will need.

John Schweitzer is vice president of EH&S and sustainability at ACMA. Email comments to jschweitzer@acmanet.org.

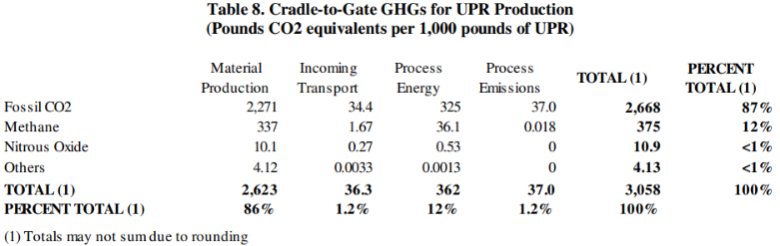

Cradle-to-Gate CHGs for UPR Production (Pounds CO2 equivalents per 1,000 pounds unsaturated polyester resin)