Eventually, Sikorsky hopes to embed the sensors in a helicopter tail boom, which holds the tail rotor assembly, and use an interrogator to read the sensors on the aircraft in the field between flights. “Whether it’s a wind blade or the composite fuselage on an aircraft, the sensor is essentially giving you information about the life of that asset so you can manage it that much better,” says Nath.

A Scalable Process

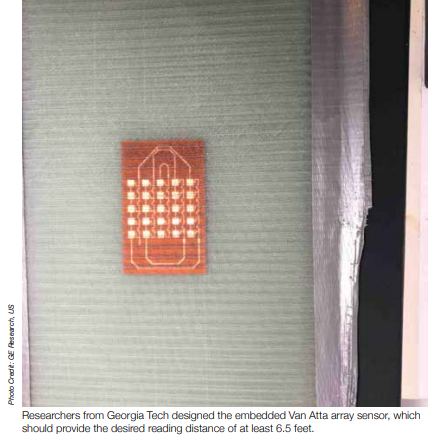

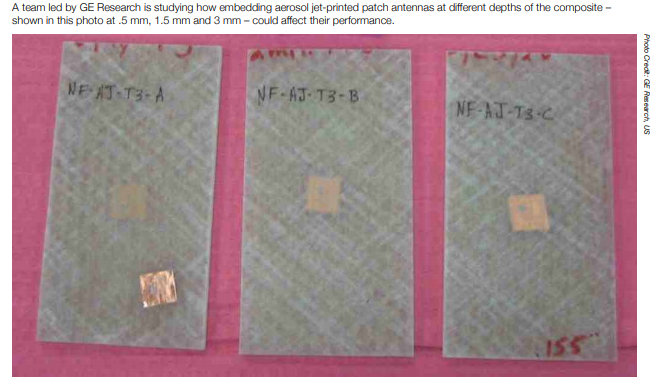

The printed sensors measure only 2 x 3 inches and are thinner than a composite ply. Although the thickness of the sensor was important to minimize its impact on the composite structure, the goal wasn’t to get the smallest sensor possible, but to develop one that would fit easily into the shape of the wind blade. The team is also investigating how many sensors would be needed to get the data it wants and where those sensors should be placed.

The researchers will not build an entire wind blade to test the concept, but are trying to demonstrate that it is possible to add monitoring FHEs to a composite material in a scalable way, according to Miller. “One of the specifications was that the project team would have to produce a composite structure with embedded FHEs that was at least three square feet,” he says. While that’s not a large size in the composite world, it is large enough to show that the insertion of FHEs could be automated and would not require a precision, hand-assembly process.

“Wind blade manufacturing is a labor-intensive process, and things haven’t changed in the last 50 years,” says Nath. “There’s a big push to go from a conventional labor-intensive process to an automated process like what’s used for automotive production.” Another driver is that wind blades are getting longer and longer, which increases manufacturing cycle time. “You want to reduce cycle time and the labor footprint, and having sensors during manufacturing could help us do that, as well as monitor the health of the blades,” adds Nath.

For example, sensors can provide real-time information about how the resin is flowing, which will help automate the resin infusion and minimize the involvement of people on the factory floor. That information will help manufacturers optimize the use of materials by reducing weight, improving the quality of the composite and reducing cycle time, says Nath.

Extending the Application

The team has made good progress since beginning the project in January 2020. They have designed and manufactured the sensors, built some coupons with embedded sensors and proven that they are able to read them wirelessly. They are currently doing coupon level mechanical tests to make sure that the strength of the composite has not been impacted by the insertion of a sensor. (The team declined to share details on how it has achieved this.) Due to COVID-19-related delays, the project will probably extend a few months into 2021.

The preliminary results have been promising. Stoffel says that once the team has successfully completed the initial project, GE will be able to implement the sensor technology into its businesses. Sikorsky would like to build upon the initial project’s work by creating a customized, field-ready interrogator, using available parts and components, that could read all of the embedded sensors at once.

There’s a variety of applications where smart composites with embedded sensors could be used, ranging from rotating and structural components in aircraft to riser pipes in the oil and gas industry. The use of reliable embedded sensors will be critical for structural health monitoring and condition-based maintenance approaches, increasing long term performance, assuring that maintenance is done when needed and reducing cost and downtime. “That is the innovation part,” says Nath. “These are passive, wireless sensors that can be embedded and read remotely, and hopefully we can leverage that technology.”