The hope is that the new technique will allow patients to avoid either invasive repair surgeries to implant plates, rods, wires and screws or external frames with steel pins drilled into the bone. In contrast, the new technique is expected to require two small incisions – one to insert the CFRP tube and another to pull it through the bone cavity. The inherent antioxidant properties of carbon may also promote faster healing than titanium or other metal implants. “We want to minimize the healing period and the trauma and make it as non-invasive as possible,” says Saadatmanesh.

Current research is focused on 4- to 5-millimeter diameter, multiaxial braided CFRP tubes that are manufactured to specifications by an outside vendor. The tubes are pre-impregnated with zinc phosphate or resin modified glass ionomer (RMGI). While it was easy to locate a manufacturer to produce the tubes, finding the right polymer to fill the sleeve presented a challenge. The team is investigating multiple bio-grade polymers – or “bone cements” – that are already approved for use in the human body.

They may also consider dental composites. Regardless of the final choice, the polymer must harden quickly and bond well with the CFRP tube. “We are in the process of investigating which one would fuse better with the carbon fiber to make the two materials work together as one,” says Saadatmanesh.

While the project was initially aimed at repair of large bones, such as leg femurs, other potential applications have emerged, including stabilization of hard-to-set ribs and collarbones. “[For these bones] there is no other option,” says Saadatmanesh. “They are just left to heal by themselves, and it takes a long time and is very painful.” Researchers are also considering preventative reinforcement of bones weakened by osteoporosis and veterinary uses, including fracture repair for horses and other large animals that must bear weight as they heal.

The proposed technique is so promising that UA Venture Capital (UAVC), an investment firm that helps finance faculty-led innovations from the University of Arizona, has invested millions of dollars in MediCarbone, the company Saadatmanesh founded to accelerate commercialization. “We look for unique, world-changing technology, and clearly MediCarbone fits that description,” says Fletcher J. McCusker, UAVC founder and CEO. “The opportunity to repair bone intracorpus with minimum invasion could drastically change how broken bones are treated.”

Creating a New Class of Prepregs

Project: Semi-pregs with through-thickness permeability

School: University of Southern California

Location: Los Angeles

Principal Investigator: Steven Nutt and Mark Anders (co-investigator)

Through the years, researchers at the M.C. Gill Composites Center at the University of Southern California (USC)

have studied ways to make composites manufacturing more cost effective and efficient. “Although autoclaves impart robustness to prepreg processing, their high cost creates a bottleneck in production capacities,” says Mark Anders, a postdoctoral fellow at USC. “Therefore, manufacturers have looked to alternative, out-of-autoclave options, such as vacuum-bag-only (VBO) oven cure.”

One of the concerns with VBO processing is that it lacks the high pressures of autoclaves to suppress defects, so removal of entrapped air is critical to production of high-quality laminates. “Any time you lay up prepreg plies on top of each other, inevitably there will be air in and between them,” says Anders. “So the question then is how can you reliably get the air back out?”

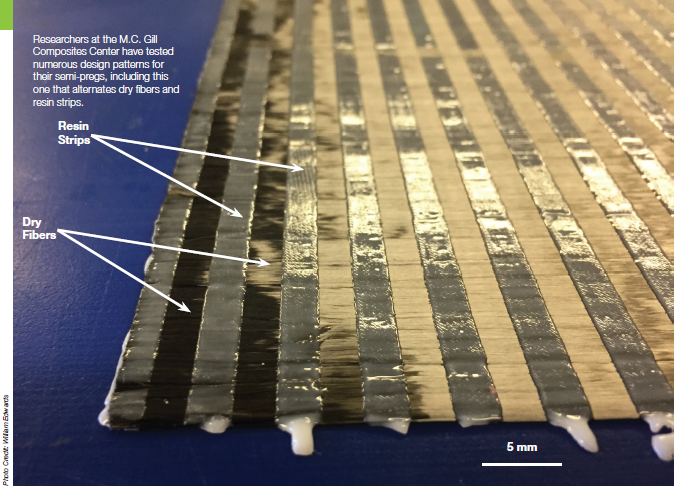

Partial impregnation enhances air evacuation, but the concept hasn’t yet been fully optimized, says Anders. Partial impregnation is typically achieved by laminating resin films onto either side of a fiber reinforcement without fully saturating through the thickness, leaving dry evacuation channels at the ply center. These VBO prepregs utilize in-plane evacuation, or “edge breathing,” but the time required to evacuate air scales to the breathe-out distance squared. “For larger parts, debulking becomes impractically long,” says Anders.

Under the direction of Steven Nutt, M.C. Gill Professor and director of the M.C. Gill Composites Center, the team at USC has been working on a solution: promote extraction of gases in the through-thickness direction of laminates, which is much shorter than the planar direction. This paradigm shift for prepreg formats relies on discontinuities or openings in the resin films coated onto the fibers, through which entrapped gases can be evacuated. “The relatively simple idea is to get the air flow out of the plane in the Z direction,” says Anders. “It really improves the robustness of out-of-autoclave prepregs if you have that feature – that out-of-plane breathability or through-thickness gas permeability.”

These prepregs – known as semi-pregs – have several advantages, according to Anders. They reduce debulk times from hours to minutes without sacrificing part quality. In addition, semi-pregs exhibit a much lower sensitivity to adverse process conditions, such as humidity and embedded ply drops, than conventional VBO prepregs.

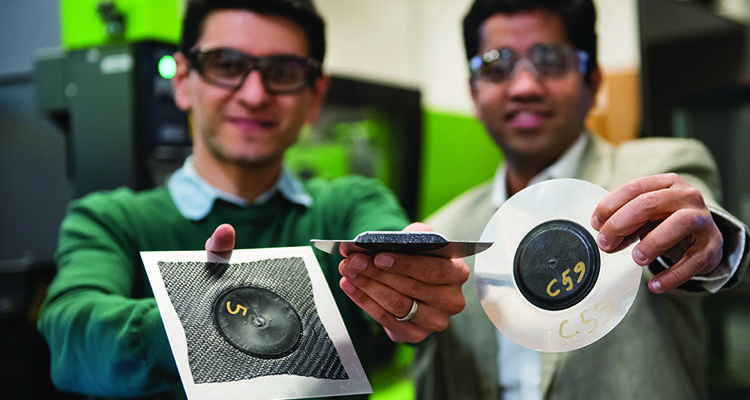

To further development of this new class of prepregs, Nutt’s team has set out to answer three primary questions: Does extraction of gases in the through-thickness direction work? How can you make these semi-preg materials? What is the best design? The first question has been answered. “Our lab has fabricated semi-pregs with through-thickness permeability using various reinforcement architectures and resin types, demonstrating the feasibility and versatility of the concept,” says Anders. To date, the team has done lab-scale work, making small quantities of laminates measuring 12 square inches or less and conducting in-situ diagnostics to better understand how the gas transport happens.

Recently, Anders has examined how to make prepreg with through-thickness permeability, testing a variety of methods in the lab. One system his team built is a printer that programs any desired pattern and could potentially make prepreg on demand. However, it’s slower than traditional prepreg manufacturing machines. Another method the team has pursued is retrofitting existing prepreg equipment to make semi-pregs. “We are looking at how to translate these ideas into something that can be done at scale and won’t cost an arm and a leg,” he says.

Finally, the researchers are looking at design options. “Suddenly, you have this whole new design space,” says Anders. “Before, you were only considering the through-thickness degree of impregnation, but now you are considering in-plane patterns in the resin.” The team has tried numerous patterns, resins and fabrics, such as stripes of resin on plain weave fabrics and “islands” or separate dots of resin on spread tows.

“The work is promising,” says Anders. “We have conceived, designed and demonstrated scalable prepregging methods.” Now the researchers are pivoting their efforts to transition the technology from the lab into commercial products.

Next Generation Military Applications

Project: Cold spray processes for polymers and composites

School: Rowan University

Location: Glassboro, N.J.

Principal Investigators: Francis Haas and Joseph Stanzione, III

Researchers at Rowan University are leading a project to pioneer cold spray of polymers and composites for potential use in next-generation military applications. The five-year, $14.5 million dollar project is a collaborative effort with the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory (CCDC ARL), the Kostas Research Institute (KRI) at Northeastern University, Clemson University, Drexel University, University of Massachusetts Amherst and PPG Inc.

Cold spray processing involves spraying of powdered material at extremely high velocities, generally hundreds of meters per second. When the sprayed particles make contact with the substrate, they flatten out and can chemically and mechanically interlock with the structure. Despite its name, cold spray is anything but cold. As Francis “Mac” Haas, Rowan University assistant professor of mechanical engineering explains, “You can get a cold spray that starts off at 700 degrees Celsius – so it is in no way cold – but it’s cold relative to its melting point.”

While cold spray processes are well-developed for metals, they represent a new frontier for polymers and composites. Adapting the technology involves several fundamental challenges. For polymers, the processing temperatures are much lower (generally between 70 and 200 degrees Celsius) and are likely to be governed by the glass transition temperature of the sprayed polymeric material.

In addition, polymers can become tacky when heated, which hinders flow for spraying. Polymers also react differently when they impact the surface. For example, deposition efficiency rates for polymers – the amount of sprayed powder that “sticks” to the substrate – are generally quite low. “You get a tiny amount of powder to stick, and even then, that doesn’t necessarily mean it will do a particularly good job, whether structurally or as a coating. That just means it’s stuck to the wall,” says Haas. “So there’s a lot of basic science that needs to be done.”

Cold spraying processes for polymers and composites are expected to enable the manufacture of functionally-graded composites that have different materials layered into the same part. Researchers believe that by changing the powder mixture they can create varied composite layers with different resins, fibers and fiber-to-resin content. Joseph Stanzione III, associate professor of chemical engineering and founding director of the Advanced Materials & Manufacturing Institute (AMMI) at Rowan, says that the layers could be made from a variety of materials, including polymer-on-polymer, polymer-on-metal or metal-on-polymer. “That’s the beauty of this project!” he says.

John La Scala, division chief for material and manufacturing sciences at CCDC ARL agrees. “It would allow you to have a layer-by-layer differentiation of properties, which could be really useful to achieve high performance,” he says. For example, combat vehicle parts could contain a hard outer shell with softer inner layers for damage tolerance – all achieved through the single process of cold spraying. The technology could also be used for rapid, in-theater repair of combat vehicles.

Hypersonic weapons, which travel at more than five times the speed of sound, are another potential application. La Scala says that cold spray processes could potentially be used to create light, strong, high-temperature resistant carbon-carbon composite hypersonic casings. Among other benefits, this would allow for pyrolysis of each carbon-carbon layer, which would reduce the voids caused by the carbonization process.

Initially, researchers worked with polystyrene because it is a well-characterized material. Now, they are focused on thermoplastics such as polycarbonate and PEEK. Next, they hope to tackle thermosets like vinyl resin and epoxy systems. Since commercially available powder polymers and composites are limited, the team is synthesizing polymers in-house, as well as adding fibers and fill and reducing particle sizes with milling, grinding and microfluidics techniques.

In the long run, this developing technology could benefit numerous industries, including aerospace, automobile and petrochemical. Stanzione and Haas are particularly excited about potential biomedical applications, such as lighter weight, more advanced prosthetics.