Dowty has made improvements to and automated many of its other manufacturing technologies as well, including blow molding capabilities for thermoset cores. The company has also worked with the Manufacturing Technology Centre, another catapult center, in the development of a process monitoring system for resin transfer molding to ensure the more complex geometries it is manufacturing will emerge from the press defect-free.

By virtue of the digital twin, Dowty designers can easily align structural design tool sets with complementary manufacturing techniques. “Aligning [materials] with the structural performance and linking the loads that you get from an aerodynamic shape back into structural design is critical for us,” Peckham says. “We can come up with some really wacky shapes that might give us a little of an edge performance-wise, but if we can’t then relate that into a manufacturable product, then it’s not feasible to produce.”

Trevarthen says the company can now deliver complex geometries while simultaneously achieving double-digit cost and throughput improvements.

Dowty has developed six prototype propeller blades. Now that research through DigiProp is complete, the next step is to move these demonstration products into tests and designs for future aircraft.

Megan Headley is a freelance writer in Fredericksburg, Va. She can be reached at megan@clearstorypublications.com.

Through close collaboration with the U.K.’s National Composites Centre, the DigiProp research program led to development of a new manufacturing process that uses a combination of bladder molding and triaxial braiding of CFRP composites.

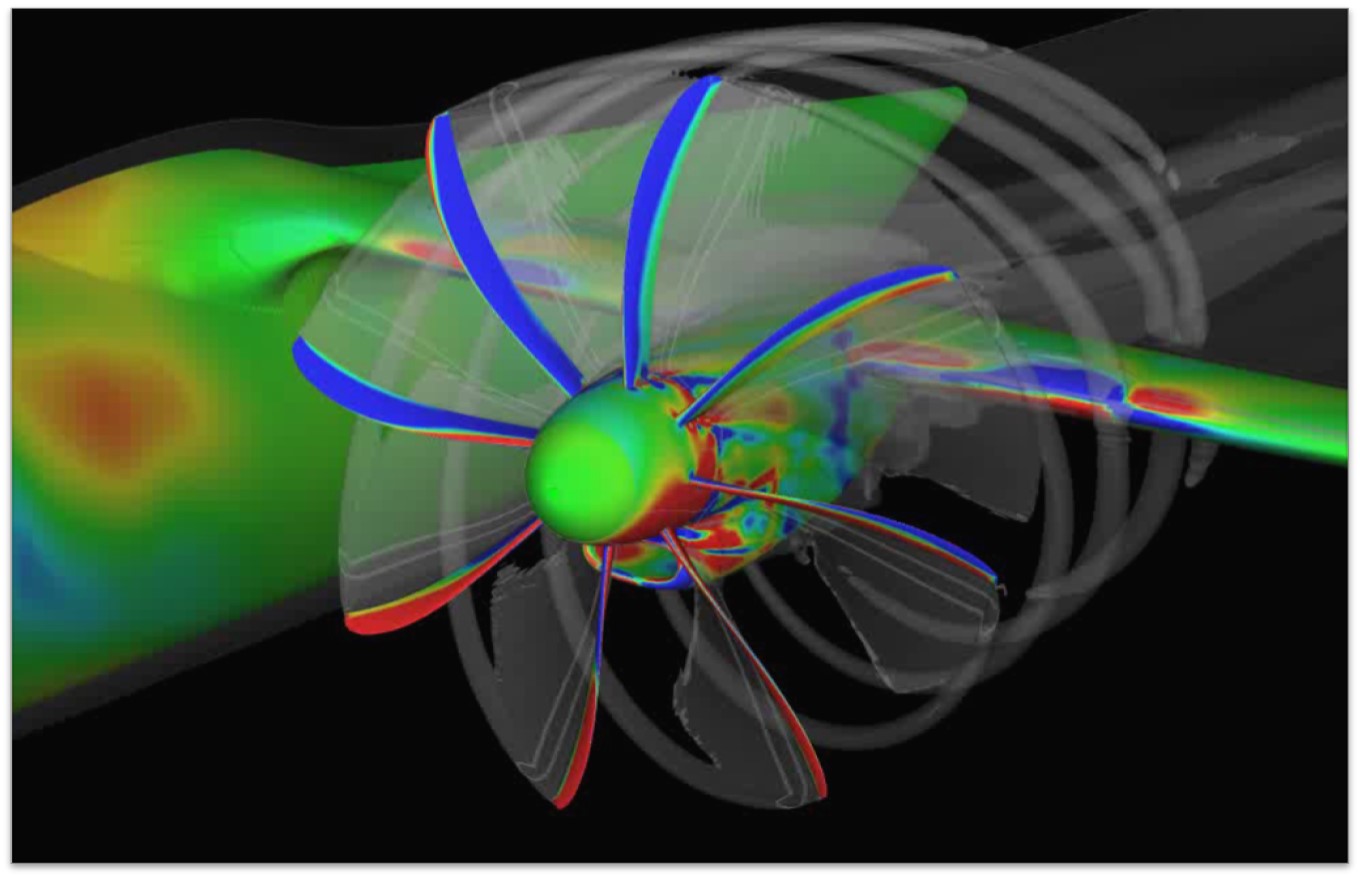

Photo Credit: Dowty Propellers

By modeling design and material options using a digital twin, Dowty Propellers can simulate the structural performance of a propeller blade before the component is built.

Photo Credit: Dowty Propellers