Gaining widespread acceptance for a new material can be a slow process. But that’s not been the case with graphene, which appears to be on a fast track to adoption in the composites industry.

Graphene, first produced less than two decades ago, is the thinnest known material. For commercial purposes, it’s defined as one to 10 layers of sp2 carbon-bonded atoms in a hexagonal honeycomb lattice. Graphene is 100 to 300 times stronger than steel, making it the strongest material ever measured. When incorporated into an FRP composite material, a miniscule amount of graphene can make a substantial difference in its properties.

“We have comparative studies where the load factor for graphene goes from .9% to .5% to .01% that still makes a 35% to 45% improvement in the mechanical properties of the composite,” says Terrance Barkan, executive director of The Graphene Council, which is leading efforts to encourage the use of graphene for commercial applications.

A Classification Framework

Initially there was only one way to produce graphene, but today there are more than a dozen manufacturing processes that use feedstocks ranging from graphite and carbon-bearing gases to biochar, oil and coal. This has increased graphene’s availability but has also caused confusion for some potential users. There’s been no effective way for them to differentiate among graphene products from various producers.

The Graphene Council has developed and recently released a solution – the Graphene Classification Framework.

“The framework is a consistent, generic way of describing any form of graphene material using approximately 19 key characteristics that are relevant for commercial applications,” Barkan explains. For example, one graphene product might be described as a mechanically exfoliated graphite, three to five layers in thickness, that is non-oxidized and non-functionalized.

“It’s not a replacement for the full characterization, but having that descriptor gives you a pretty good idea of what material you’re dealing with,” he adds.

The framework provides a template for a technical data sheet that producers can fill out to provide in-depth characterization of their graphene.

Equipped with this information, companies interested in using graphene will be able to find multiple sources for specific types of graphene material and have confidence that all the products will have consistent properties and characteristics. In addition, the Graphene Classification Framework will enable health and safety regulatory agencies, which must approve graphene’s use, to differentiate among various types of the material.

An ISO working group is also reviewing the framework with the goal of adapting it to create an international graphene standard.

Automotive Applications

Graphene producers have been working closely with manufacturers to incorporate the nanomaterial into composite materials. Manufacturers of some high-end products have been including graphene in their mixes, but the graphene industry strives for wider usage.

Versarien PLC, based in Gloucestershire, United Kingdom, has significantly increased production of its graphene powder products over the last two years, including its flagship product Nanene™, hoping to expand the graphene market into larger-volume, lower-priced applications.

“Five years ago, we were producing a few grams a week. We’re now up to 10 tons a year, and probably in the next year or so we’ll be tenfold that,” says Jim Barnett, Versarien’s head of program management.

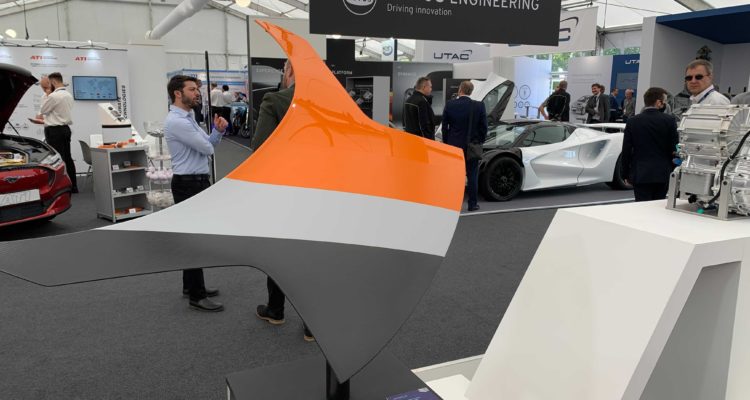

The automotive industry is a potential large-volume customer. In one demonstration project, Versarien’s subsidiary, 2-DTech, worked with Lotus Cars, University of Sheffield’s Advanced Manufacturing and Research Centre (AMRC) and several composite supply chain companies to produce a graphene-enhanced CFRP hood for the Lotus Evija electric sports car. By determining the optimal amount of graphene to include in the prepreg resin for the hood, the group improved the component’s mechanical performance by 10% and produced a surface that met Lotus’ paint specifications.

Graphene’s multi-functional nature makes it useful for a variety of automotive parts, says Steve Hodge, chief technology officer at Versarien. Graphene-enhanced composites could be used for a vehicle’s structural panels and interior parts, where the nanomaterial’s high thermal decomposition temperature could also reduce fire risk.

“Graphene has good electrical performance, high mechanical strength, good thermal conductivity and optical properties. It’s a chemically robust material; it doesn’t degrade until you get to very high temperatures. We can actually modify the chemistry of the surface quite easily to make it more compatible with certain resin systems,” says Hodge. “So really, it’s like a toolkit that enables us to modify and enhance any composite material.”

He believes automotive companies and composites manufacturers will be more likely to incorporate graphene into vehicle components once they feel confident that graphene producers can deliver the nanomaterial in the quantity and at the consistent performance levels they require.

Graphene-Enhanced SMC

In 2021, graphene producer NanoXplore opened a fully automated production plant in Montreal that makes two grades of graphene powder using a liquid exfoliation process. The company also operates a composites business unit that manufactures finished parts, primarily for the heavy-duty truck and bus industry. Tarek Jalloul, the company’s technical project lead, says that vehicles with graphene-enhanced SMC exterior panels should be available commercially within the next few months.

The company is working with an industrial partner to produce a proprietary graphene-enhanced SMC compound that it will use to manufacture composite parts, as well as brand and sell under the NanoXplore trademark to other molders.

The main value proposition for transportation customers is lightweighting. NanoXplore maintains the same fiber loading levels in the SMC as it previously had and adds graphene to further improve the mechanical properties. That enables automotive suppliers to produce lighter, thinner parts without diminishing their strength.

“OEMs get to use less SMC material to produce parts of equal performance at a cost-neutral point,” says Jalloul. The inclusion of graphene also encourages better flowability of the material within the mold, enabling the creation of more complex geometric shapes, and provides an aesthetically improved surface finish with better weatherability performance.