During the last decade, 3D printing utilizing printable polymers has gained traction. This column will cover pivotal advancements in additive manufacturing, as well as differences between thermoplastic and thermoset technologies for making molds using additive methods.

One of the most significant developments was the introduction of large format, 3D printing in 2014 under a Cooperative Research and Development Agreement (CRADA) between the Manufacturing Development Facility (MDF) at Oak Ridge National Laboratory (ORNL) and Cincinnati Inc. (CI). The joint effort led to commercial development of CI’s BAAM™ printer using a high throughput extrusion process that could melt and deposit multiple pounds of thermoplastic beads using a precise additive manufacturing process. The printer utilized an 8-foot-wide, 20-foot-long moveable print bed that was far larger than any polymer printer at the time.

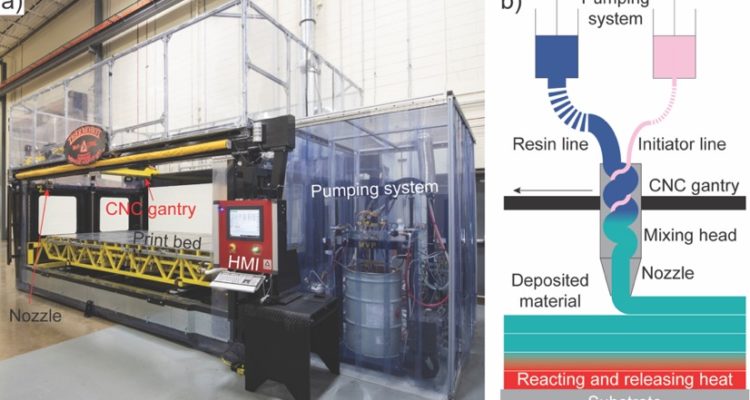

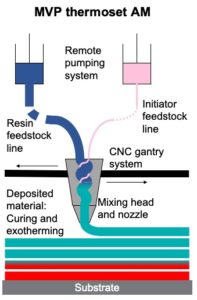

In 2017, Magnum Venus Products (MVP) launched a 3D printer line known as Reactive Additive Manufacturing (RAM). RAM printers are unique from other large format printers in that they use liquid, thermoset-based materials that are pumped and combined with an organic peroxide and deposited in successive layers.

Early development work was done under joint development agreements at ORNL’s MDF for the RAM printer and Polynt Composites for material development. Much of the RAM work at ORNL has focused on using Polynt Reactive Deposition (PRD) print media, which are viscous, toothpaste-like liquids incorporating vinyl ester resins. PRD print media is room temperature activated and solidifies within 15 to 30 minutes after deposition. Pumpable PRD materials are easier to process and require much less energy to manufacture than alternative thermoplastic materials.

Thermoset additive manufacturing (TSAM) development work is currently shared between ORNL, Mississippi State University, MVP and Polynt. A key characterisitic of TSAM is that the pumpable liquid chemically reacts with the surface of the prior beads and substrate during its cure cycle. This chemical reaction of layers is one of the major advantages of TSAM over thermoplastics, which have no chemical bonding, but are only mechanically joined by fusion.

In thermoplastics, timing is critical to melt a new bead into a previously deposited bead. Failure to melt two beads together will result in issues with bead-to-bead adhesion and can create voids, causing visual cosmetic defects, bond line failures and loss of vacuum integrity, especially when building tooling used for manufacturing parts. Another issue with thermoplastic deposition is anisotropy, which occurs when fiber reinforcements are extruded in a solid media.