Larger companies usually lead new technology adoption because they have the necessary hardware and software budgets. But the advent of cloud computing is a game-changer for small to medium-sized organizations.

A recent article from Deloitte noted that the increase of cloud-based and software-as-a-service models for AI and machine learning (ML) have made the technologies more affordable for midsize and small companies, which are taking advantage of the opportunity to digitally transform their businesses.

A variety of AI solutions are becoming available to composites manufacturers. Here are just a few.

Speeding Tool Production

Designing and manufacturing tooling is often a costly, time-consuming process and a big barrier when it comes to OEMs choosing composites over steel and metal for components, says Martin Oughton, CEO and co-founder of Plyable. His company has developed a cloud-based, AI software that speeds this process.

A customer uploads a CAD file of its desired composite component into Plyable’s online software tool and indicates its preference for material, tolerances, manufacturing method, finish and delivery date. The system’s ML algorithms automate the tool design process, assessing different tool geometries before choosing the best option. The AI software then draws upon an extensive database of supplier information to develop a quote based on the tool’s size and geometry and on up-to-the-minute material prices and market conditions. The entire process, from design to quote, takes less than a minute.

Once the client accepts the quote – usually three to five days – Plyable sends the bid out to its network of carefully screened tooling providers, which includes more than 1,500 five-axis CNC machines and some additive manufacturing options as well. The jobs are awarded quickly, on a first-come, first-serve basis, and production begins almost immediately. The client can use Plyable’s system to track the tool’s progress and review production and inspection reports.

Oughton says that smaller Tier 2 and Tier 3 aerospace suppliers, as well as OEMs and Tier 1 companies have already used the AI tooling system. He believes that technologies like these will improve composites’ competitive position.

“Composites have long been talked about as the material of the future, but I think they are in danger of always being just the material of the future, not the material of now,” says Oughton. He asserts Plyable’s technology is open to all companies and can lower the barriers to a wider adoption of composite solutions.

Automating Inspection Processes

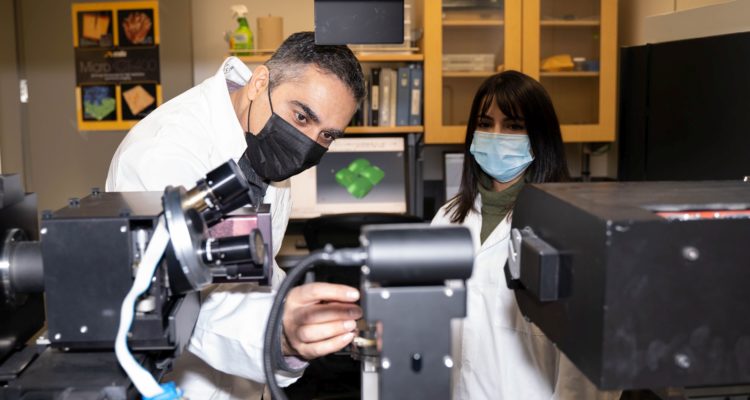

Automated fiber placement (AFP) has significantly improved the production rates and quality of composites manufacturing. “But due to the lack of reliable, in-process inspection technologies, AFP processes are currently interrupted intermittently for manual inspections – anywhere from 20% to 70% of production time,” says Waruna Seneviratne, director of the Advanced Technologies Lab for Aerospace Systems (ATLAS), National Institute for Aviation Research (NIAR).

His research team hopes to significantly reduce that downtime with an in-process AFP manufacturing inspection system (IAMIS) made with off-the-shelf laser and camera systems. Attached to the AFP placement head, the IAMIS creates a digital manufacturing twin (DMT) of the part. Using machine-learning algorithms, the system analyzes this digital data. It detects manufacturing effects that are above acceptable limits, reducing time-consuming and operator-dependent manual inspection processes that require interrupting the manufacturing process. Furthermore, it records the locations of the part’s allowable defects (those that do not require repair). Having this record can be useful when the part gets damaged during service, since it provides technicians with a better way to assess the potential damage in a given area.

The system’s AI also analyzes the digital twin to detect any gaps, overlaps and other manufacturing anomalies in the part. Based on this information, system operators could adjust manufacturing processes like laydown speed, heat input and compaction force to reduce manufacturing defects on future runs. This could improve the quality of parts by 10 to 20%, says Seneviratne.

After several successful demonstrations of the IAMIS, researchers will mount the system on production lines of several aircraft manufacturers, including those in the advanced air mobility market, within the next few months. The manufacturers will continue manual inspections at the same time to compare results with those from IAMIS.

“Advanced air mobility companies want to make thousands of airplanes a year but using the AFP machine the way we do today they’re not going to make 1,000,” says Seneviratne. Eliminating the manual inspection process and employing IAMIS – with a fully-trained ML algorithm – could decrease the time required to fabricate a part by 20% or more and reduce the cost by over 30%.

“Eventually, we want to convince the FAA and the certification authorities that the IAMIS system is either equivalent or better than manual inspection,” Seneviratne adds.

Improving the Supply Chain

Many large industrial manufacturers have implemented AI and ML-based supply chain management programs to optimize supplier selection and flag potential problems. To be effective, these systems use data that’s pulled from the organization’s enterprise resource planning (ERP) systems, supplier lists and other sources stored in the cloud.

But getting that data input can be problematic for the many composites manufacturers that have not digitalized their operations. “A lot of their data is still in Excel sheets, in registers, in notebooks somewhere,” says Rajeev Sharma, chief technology officer at Grid Dynamics.

A company that wants to digitize and gather data to move to an AI model for supply chain must remember that AI should be used to solve their particular business problems, Sharma says. For example, if a manufacturer decides to work with a tech provider like Grid Dynamics to construct an AI supply chain model, it will most likely start by building a database with basic supplier information like location and materials costs. Then, if the company’s primary business concerns include material availability and pricing, it might include inflation data, weather data or even political data in its AI model. That enables the model to train on those factors and include them in the algorithms for making purchasing recommendations.

“Suppose you have 1,500 suppliers in your database; you know where they are located and you know their regular prices,” says Sharma. “Now imagine that some of those suppliers are in a part of the world where there is a hurricane. If your system is integrated with weather data and price data, and if you have an AI model trained for weather impact on your business, your AI engine can tell you which of your suppliers are at risk and how it could impact your raw material prices and your delivery schedule.”

The AI model could even provide a visualization on a Google map of which routes would and would not be disrupted. “All of this is done autonomously, without anybody having to press any button,” says Sharma.

Creating a Safer Workplace

Companies that have invested in closed circuit television systems for security could use AI to increase their return on investment.

“CCTVs aren’t well utilized. They have to be manually monitored by a person or looked at retroactively after some occurrence to understand what happened,” says Josh Fox, director of product marketing, AI technologies at SparkCognition.

It has developed a platform that taps into a company’s existing CCTV infrastructure and uses SparkCognition’s Visual AI Advisor to monitor, analyze and interpret the activity the camera captures. A composites manufacturer or materials supplier could use the cloud-based system to look for security lapses or safety violations.

The system includes pre-built use cases that cover areas such as health and safety, physical security, productivity and situational awareness. “A use case is a combination of a computer vision model and business logic rules that enable some sort of response or action to occur,” Fox explains.

The AI monitors the camera feed in real time and compares workers’ actions to the acceptable behaviors defined in the use cases. For example, the system’s ML component can be trained to distinguish between someone who is wearing a hard hat and someone who is not. If the AI detects someone without the required personal protection equipment, it can send an immediate alert or flag the occurrence for future employee training.