Several years ago, Suong Hoa heard a seminar on 4D printing from one of his peers at Concordia University that piqued his interest.

“He was using polymers with shape-changing properties that react to a particular stimulus, such as water or heat,” says Hoa, a professor of mechanical, industrial and aerospace engineering and co-director of the Concordia Centre for Composites. “The idea came to me that we could use 4D printing to make complex composite shapes without the need for molds.”

Since then, Hoa and students at the Centre for Composites have printed and tested various components, including an S shape and a leaf spring. Most recently, they manufactured and performed a feasibility study on adaptive compliant trailing edge (ACTE) morphing wings for unmanned aerial vehicles (UAV) that can replace the frequently used hinged wing flap with one that attaches to the main body wing. The 4D-printed ACTE wing has a flex angle up to 20 degrees.

“Our study shows that a UAV using this kind of wing can support a good amount of load for small or medium-sized vehicles,” says Hoa.

The 4D printing technology developed by Hoa takes advantage of the asymmetry of composite materials.

“Rather than looking at anisotropic properties as a liability, I viewed them as an asset,” he says. “We utilize those properties to make a shape without the need for a mold.”

Standard 4D printing is like 3D printing, however it changes material from location to location. In 4D printing of composites, the material stays the same within a layer, but the fiber orientation changes from layer to layer.

Hoa’s team creates composite structures using an automated fiber placement machine that is similar to a large 3D printer. The machine unrolls carbon fiber prepreg with 10-micron fiber filaments in ultra-thin layers at 90-degree angles from each other onto a flat mold. The layers are then compacted together and cured at 180 C in either an autoclave or oven to create the solid laminate. After curing, the composite structure is cooled to 20 C. During this process, the flat structure becomes curved. The fourth dimension refers to this altered configuration.

The ACTE wings are made from corrugated composites to provide stiffness in the span direction and flexibility in the chord direction. They feature two primary parts – a rigid support section and the active compliant trailing edge, which is fabricated from GFRP skins. Sliding between the upper and lower wing skins, which are connected by linear pair guides, allows the ACTE to achieve a large, continuous bending deformation.

While Hoa and his students are currently refining the analysis, design, manufacturing and testing of the ACTE wings, they have their eyes set on future applications that offer promise for commercialization. For instance, 4D composite printing is well suited for vertical-axis wind turbines, where the main rotor shaft is arranged vertically.

“There are a lot of twists and complex curvature,” he says. “If you were to make a mold, it would be very costly. I have also seen manufacturers construct a flat piece that they bend, and it cracks in multiple places. We should be able to utilize the properties of composites to do a better job.”

Hoa wants to spread the word about the potential of 4D printing.

“When people see 4D printing, they think about plastics. Few people are familiar with the technique for composites,” he says. “Hopefully, people will be open to the new technology.”

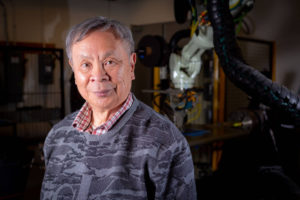

Suong Hoa, co-director of the Concordia Centre for Composites at Concordia University, has developed a 4D composite printing technique.

Photo Credit: Concordia University

Solving the Housing Shortage

Project: Sustainable 3D-printed Houses

School: The University of Maine

Location: Orono, Maine

Principal Investigator: Habib Dagher

A team of researchers at the Advanced Structures and Composites Center (ASCC) at the University of Maine are turning to technology to solve a societal concern. They believe 3D printing can help fill the void in low-income housing.

“In the United States, there’s a need for 8 million low-income houses,” says Habib Dagher, professor of civil and structural engineering at the University of Maine and director of the ASCC. “To solve the problem, we need to automate processes and drive costs out of the system. It’s not an easy road forward.”

The ASCC researchers are collaborating with Oak Ridge National Laboratory and the Maine State Housing Authority to design and 3D print a prototype house using sustainable composite materials. These include wood materials, such as sawdust, to create wood flour that is combined with biopolymers to create pellets for 3D printing.

The project falls under the umbrella of the ASCC’s 2020 strategic plan, named Green Energy and Materials (GEM).

“Our goal is to bring green energy and materials to society,” says Dagher. “From an environmental perspective, using bio-based materials – whether from trees or other sources – is an important part of the global fight against climate change.”

As part of this mission, the center first printed a tri-hull boat nearly three years ago. The 25-foot-long, 5,000-pound boat was printed in just three days.

“We validated the feasibility of manufacturing a large structure in one go,” says Dagher. Since then, the ASCC has 3D-printed numerous structures.

The center finished printing the prototype house in October and has placed it outside the lab to go through “the good, old Maine winter,” says Dagher. The weatherproof house, which is heated and fully operational, incorporates sensors to gauge energy efficiency, structural performance, dimensional stability and air quality.

“The house itself is a milestone, of course, but we are focused on advancing material and manufacturing technologies that enable us to build the house,” says Dagher.

To achieve those goals, the ASCC is collecting data every time it uses the printer, including bead properties, the height and elevation of the printhead, machine temperatures, environmental conditions and more. In addition, the team scans each part it prints and collects data, such as part temperature over time.

“All of the data goes into a data bank with a high-performance computing platform,” says Dagher. “We can query the data bank to better understand the relationship between process parameters and the quality of the part we get at the end.” In the next few years, the team plans to add artificial intelligence to the printers.

“You will have smart printers that learn as they go, which is really important for very large prints,” says Dagher. “When you 3D print something on your desktop and make a mistake, you can just print another one. But when you have something 30 x 20 feet and weighing 40,000 pounds, you can’t really do that.”

Everything that the ASCC team is learning will help them build the GEM Factory of the Future, where the production process will scale up to manufacture boats, homes and other structures in larger volumes. Dagher anticipates the Factory of the Future being operational in 2025. He hopes it will have a sweeping impact across industries – including the housing market.

“We will not solve the housing problem overnight,” says Dagher. “We’re looking at radical solutions to solve the problem over the next decade, and 3D printing of homes with bio-based materials is one radical solution.”

The Advanced Structures and Composites Center 3D printed a prototype house using sustainable composite materials on its custom Ingersoll MasterPrint® 3X, which features an integrated CNC 5-axis machine for cutting, surface finishing and part geometry finishing.

Photo Credit: University of Maine

Susan Keen Flynn is managing editor of Composites Manufacturing magazine. Email comments to sflynn@keenconcepts.net.