My first concern is that EPDs are much better at conveying information about cradle-to-gate impacts, while composite products are typically chosen for their use-phase benefits. The composites industry will have to convey information about the benefits of our products using methods that complement EPDs and support better-informed decision making by infrastructure owners and material specifiers.

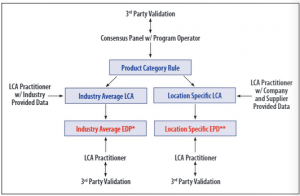

Further, producing and maintaining EPDs is costly and burdensome. Figure 2 illustrates the complexity of this process. Our competitors have both more resources for this and less complicated supply chains. ACMA is considering a composites industry EPD program that could lessen the burdens on individual composites manufacturers.

Additionally, it’s not clear that end users and material specifiers will find EPDs for composite products to be all that useful. The composite products used for a construction project are likely to represent only a small fraction of the climate or other environmental impacts associated with the entire project, especially if only cradle-to-gate impacts are considered. Requirements to consider EPDs could become just a check-the-box exercise for many types of infrastructure projects.

Other groups representing both suppliers of construction products and contractors share these same concerns. Many are likely to call on the EPA to limit EPD requirements to projects above a certain size and, on those projects, to materials that comprise more than a certain share of the total cost of a project.

But no one believes EPDs can be completely avoided by manufacturers selling products into infrastructure markets, despite the problems and challenges.

ACMA members should keep an eye out for the Insider e-newsletter, which provides up-to-date information about EPDs and the association’s sustainability programs.

John Schweitzer is vice president of EH&S and sustainability at ACMA. Email comments to jschweitzer@acmanet.org.

Figure 1: Example Industry Average LCA

Impacts of the production of 1,000 pounds open molded composite, from an industry average cradle-to-gate assessment:

| Impact | Units | Quantity |

| Cumulative energy demand | Billion BTUs | 13.9 |

| Water use | Gallon | 447 |

| Solid waste generated | Pounds | 173 |

| Climate warming gas emission | Pounds CO2 equivalent | 1,547 |

| Styrene emissions | Pounds | 7.1 |

| Other VOC emissions | Pounds | 0.51 |

The EPD process shown here must be repeated every five years.

* One industry average EPD per product type

** For each product type, one EPD for each location where the product is made