“A wind blade consists of up to 10 different materials, so chemical recycling all of these streams into one place will never be sustainable because you need so many processes,” says Hülya Ucar, materials and recycling specialist at Continuum. “With mechanical recycling, we can do everything in one process. It is a technology that can solve this problem in a way that is environmentally sustainable and also economically feasible.”

Wind blades, thermoset composites and glass fiber or other non-metallic fiber materials bonded with epoxy, polyester, polyurethane and vinyl ester resins can all serve as feedstock for the process. Fines (crushed or powdered material) and fibers from manufacturing waste can also be recycled.

“The feedstock is fed in large pieces into the factory, where it is crushed and then fed through a series of cutting, milling, separating, sorting, screening, sifting and cleaning sub-processes until pure, clean material is put into storage hoppers,” says Derrien, chief investment and development officer of Continuum. The polyurethane fillers and epoxy resins that are detached from the glass fibers are segregated in fine, granulated form.

Continuum’s method also separates out more than 90% of any carbon fiber embedded into the wind blades. It’s then sent to companies that specialize in carbon fiber recovery. Copper, aluminum, non-ferrous metals and small contaminants like stones or pieces of rope are either recycled or disposed of.

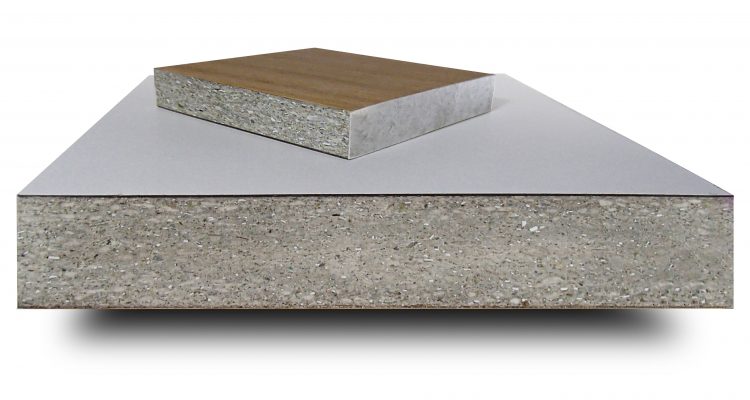

In the second stage of the process, the materials that have been separated into different silos are mixed, with a low percentage of virgin resin mixture, to form a new type of composite material. “We have about 20 different properties that we can adjust, some more than others, based on the performance requirements for each panel,” says Derrien.

The third step is the formation of the panels, which are themselves fully recyclable. The formaldehyde-free panels can range in thickness from .23 to 1.5 inches and are manufactured in the same lengths and widths as competing wood fiber or cement panels. Continuum’s products are moisture-resistant and have a strength comparable to or higher than their conventional counterparts, Derrien says. They are a good choice for building facades and for floors and countertops in bathrooms and kitchens. Customers can finish the panels with paint or another coating.

Continuum’s first factory will open in Esbjerg, Denmark, by the end of 2024, with a second factory in the United Kingdom not far behind. The company also plans to build factories in France, Germany, Spain and Turkey by 2030. Each factory should be able to manufacture 30,000 cubic meters of the new composite panels each year while recycling 36,000 tonnes (approximately 79.4 million pounds) of end-of-life composites.

Derrien says Continuum’s process is energy efficient, sustainable and cost-efficient, which makes it competitive in both the feedstock and end product markets. “It is a green product that is becoming a key differentiator in an industry looking to de-carbonize,” he says.

Increasing the sustainability of composite materials is essential to the industry’s future. Although the challenges of dealing with end-of-life wind blades won’t be resolved quickly, the number and variety of reclamation methods being developed today hold promise for viable solutions in the not-too-distant future.

Mary Lou Jay is a freelance writer based in Timonium, Md. Email comments to mljay@comcast.net.

The glass fibers recovered from the University of Tennessee, Knoxville’s new modified pyrolysis process are purer and more valuable for commercial applications than those recovered in a traditional pyrolysis process, according to university researchers.

Photo Credit: Ryan Ginder, UTK

Rolls of nonwoven fabrics, made from recycled glass fibers recovered through UTK’s modified pyrolysis process, can be used in applications like boat construction.

Photo Credit: Ryan Ginder, UTK

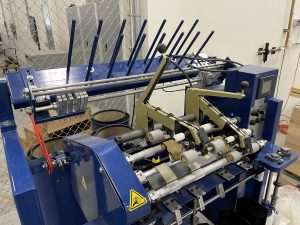

TPI, Carbon Rivers and UTK developed modified versions of a textile carder and spinner (shown here) to create a blended recycled glass fiber/continuous synthetic filament yarn with promising properties.

Photo Credit: Steve Nolet, TPI