ASCC’s thermoplastic pultrusion line has been designed in modular form so that researchers can change the heating, cooling and consolidating processes depending on the type of thermoplastic material combinations that they want to use.

The team has done some initial testing of the GFRTP pultruded rebar, looking at factors such as the shear transfer between the rebar and the concrete, the properties of thermoplastic rebar with different diameters and materials, and its performance in reinforced concrete beam failure tests. Over the next year, researchers hope to obtain funding to compile a comprehensive database of these and other properties of the rebar, including its tensile strength, environmental durability, moisture absorption and reaction to alkaline environments. They will also develop a process for heating and bending the rebar on site.

Lopez-Anido says other issues that need study include thermoplastic creep and deformation and the type of protection that might be needed to shield the rebar in the event of a fire.

ASCC’s research has already shown GFRTP pultruded rebar could provide many benefits as an alternative to traditional rebar. Sustainability is one big plus. In addition to thermoplastic rebar being recyclable, it is made using a low-VOC continuous manufacturing method that reduces environmental impact and health risks.

Another thing that could make thermoplastic rebar attractive to the construction market is its competitive price. Lopez-Anido estimates the cost of producing the pultruded thermoplastic rebar with the CFM would be 60 cents a foot, which is in the same price range as traditional rebar.

Bending Thermoplastic Reinforcements

Over the last three years, researchers on the DRIFT project, funded by the German Federal Ministry of Education and Research, have explored the integration of load-bearing elements in an injection molding matrix. Composite parts produced through this process might be used for structural automotive parts and for parts that reduce a vehicle’s noise, vibration and harshness (NVH).

DRIFT’s goal was to show that a process combining thermoplastic pultrusion, industrial wire bending and injection overmolding was feasible. Researchers at Fraunhofer IGCV, who focused on the thermoplastic pultrusion step, worked with other development partners to successfully develop this combined production technology.

During the project’s first year, the researchers compared the benefits and disadvantages of three pultrusion processes: melt, mingled yarn and reactive. They eventually chose the melt pultrusion process because of the variety of materials that could be used in it and its higher predicted bonding in the injection-molded process. The challenges of melt pultrusion were scalability, melt viscosity, tooling complexity and the additional investment required for an extruder.

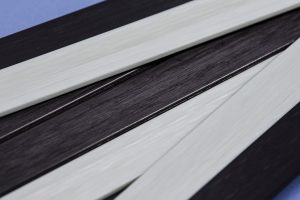

The team initially used a combination of glass fiber and polypropylene (PP) to manufacture the pultruded profiles. Later in the project, to further test the process and the properties of other material combinations, they combined glass fibers with polyamide 6 (PA6) and then carbon fibers with PA6 and PP. Researchers tested all the combination samples for fiber volume content, tensile properties and bending properties.

“The process isn’t limited to the four material combinations we used,” says Maximillian Rieger, group lead in pultrusion at Fraunhofer IGCV. He expects it will take just a few weeks to make the necessary adjustments to optimize the process and find the right temperatures for a variety of other materials. Options could include PEEK or PAEK, which might lead to the technology’s application in the aerospace industry.

The DRIFT team worked with equipment manufacturer WAFIOS to develop a bending machine for shaping the thermoplastic pultrusion rod into the desired shape for the automotive part reinforcement. Once the rod was bent, it was ready for the overmolding process.

With the use of automated technology, the researchers demonstrated that it is possible to pultrude, bend and insert thermoplastic reinforcements into automotive parts in a relatively short time. In addition, efficient raw material utilization would result in very little scrap.

“In the end, the DRIFT project was basically lessons learned from all the different partners and all the different work packages,” says Rieger. “We identified the weaknesses and the things that we need to work on.” The group applied for funding for a three-year follow-up project to take the process to a higher technical readiness level and push it into the industry for mass production.

The introduction of any or all these thermoplastic pultrusion processes to the market could provide customers in automotive, aerospace and other industries with another valuable tool for composite parts manufacturing.

Mary Lou Jay is a freelance writer based in Timonium, Md. Email comments to mljay@comcast.net.

Researchers at Fraunhofer Institute for Chemical Technology ICT used a reactive process to produce pultruded, thermoformable profiles.

Photo Credit: © Fraunhofer Institute for Chemical Technology ICT

Researchers at the University of Maine’s Advanced Structures & Composites Center developed a continuous forming machine that produces pultruded thermoplastic rebar with PETG.

Photo Credit: Roberto Lopez-Anido

The equipment developed by the DRIFT project researchers for pultruding glass fibers and PA6 could be adjusted to handle other fiber and resin combinations.

Photo Credit: Maximilian Rieger