The 8,000-pound bronze International Friendship Bell in Oak Ridge, Tenn., was installed in a park in 1996 to symbolize the spirit of peace and friendship shared between the cities of Oak Ridge and Naka, Japan. A newly-constructed pavilion added last year features freestanding CFRP beams over the bell that are also symbolic, representing a bridge between traditional design and radical innovation in architectural applications. The curved beams are not only eye-catching to the public, but they also provide an opportunity to educate the architectural community about the possibilities of composites.

Even the architect who designed the beams had an eye-opening experience working on the pavilion design. “The architect mentioned that when it comes to new projects, he will start thinking of composites more in the future,” says Uday Vaidya, chief technology officer at the IACMI—The Composites Institute and UT-ORNL Governor’s Chair, University of Tennessee, who helped spearhead the project.

Although composite materials have pushed boundaries in architectural applications in recent years, many architects remain largely unaware of the benefits of composites in architecture and how best to utilize FRP materials. Projects like the Friendship Bell pavilion are helping to educate them.

“Finally, after years of missionary work, I think most architectural firms are now familiar with the term FRP,” says Bill Kreysler, president of the engineering and fabrication firm Kreysler & Associates in American Canyon, Calif. “Now it’s a matter of educating those architects and engineers about where and when you should and should not consider FRP.”

A Striking Pavilion

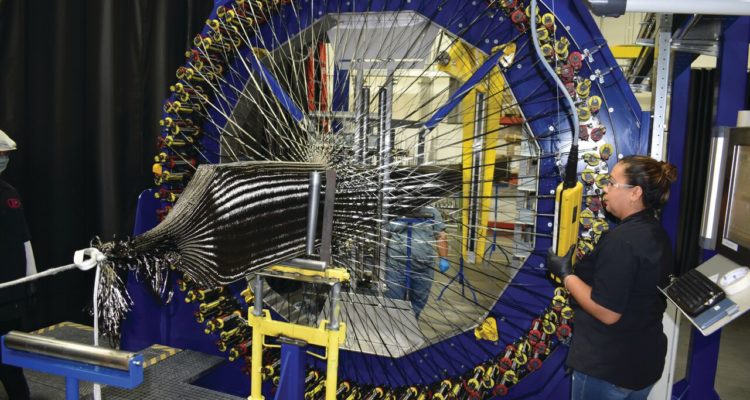

The park where the International Friendship Bell resides was renovated in 2018 to create a larger plaza around the bell and a pavilion where visitors could gather for thoughtful reflection. The curved beams, which are the world’s largest overbraided structure, were developed by several expert organizations in the composites industry. Knoxville-based IACMI brought together Oak Ridge National Laboratory’s Carbon Fiber Technology Facility, the University of Tennessee and the overbraiding experts at Highland Composites in Statesville, N.C.

That local carbon fiber expertise, coupled with the innovative concept from Ziad Demian of Demian Wilbur Architects, gave composites an edge in being specified for the pavilion. Composites also provide the required stiffness to achieve the large length desired for the pavilion beams – 33 feet – as well as light weight, durability and easy installation.

To park visitors, the pavilion may seem deceptively straightforward. Above the bell, 17 free-floating arched beams cantilever from a central concrete/steel superstructure. To create the appearance of an open dome for anyone standing beneath the structure, each beam features an entirely different arc radius.

Because there was no consistency among the beams, molds were immediately ruled out. From there, the University of Tennessee/IACMI team was challenged to develop a cost-effective method for manufacturing 17 unique CFRP beams.

“Many factors went into determining the easiest and cheapest way to produce this without a mold because it had to be a continuous chain for each different arch for the beam,” Vaidya explains. Ultimately, the team hit upon a combination of vacuum infusion, braiding and overbraiding.

“Braiding technology is unique in that it’s able to bring in fibers from different angles and strengthen those based on direction,” Vaidya says. Each beam began with a high-performance polyurethane foam core that was curved to the desired shape. Next, the foam core was sent through a braiding machine where Toray T700 24K standard modulus carbon fiber was wrapped around the foam in a triaxial architecture. Finally, the overbraided form was vacuum infused with a thermoset epoxy resin, fully encapsulating the core.

“This being a prototype, we learned as we went,” Vaidya adds. “It took us about six weeks to produce these 17 beams. I believe if this were an industrial scenario you could probably make them in a week.” The carbon fiber braided arched beams won the Award for Composites Excellence (ACE) for Most Creative Application at CAMX 2019.

Advantages that Appeal to Architects

The Friendship Bell Pavilion highlights one of the primary attractions of composite materials in architecture – their ability to create any shape.

“Shape continues to be attractive to architects, and certain shapes are just problematic to do in concrete and steel and aluminum,” says Andy Bridge, vice president of industrial markets and director of research and development with manufacturer Janicki Industries. “So, architects find themselves intrigued by or having to turn to composites.”

Sustainability also resonates strongly with architects, and this “green” focus could help garner greater interest in composites. While composite materials’ documented durability attests to the fact that it can lengthen a project’s lifespan, designers may be more interested in the integration of recycled materials to create architectural structures.

The Meteghan River house in Nova Scotia, which Composites Manufacturing magazine featured in its September/October 2019 issue, is a case in point. JD Composites Inc. built a 2,000-square-foot waterfront home featuring engineered beams and walls made from Armacell’s 100% recycled PET foam panels. The product has been tested to withstand a Category 5 hurricane, achieves an R30 insulation value and diverted about 612,000 plastic bottles from landfills in the process.

“There are at least five or six of these kinds of projects around the world on paper,” says Sam Ang, business development manager – Americas for foam manufacturer Armacell. The problem, he says, is that most people are waiting for government grants or other funding before diving into the testing needed to prove the benefits of a composites house. And, in a classic Catch-22, few of those grants are offered before testing proves the feasibility of a composites house.

Tiny Homes, Big Potential