Perhaps now more than ever, university research is critical. Inquisitive researchers on campuses across the U.S. are working on projects related to materials, technologies, processes and applications in the composites industry that have the potential to not only shape the industry itself, but also bolster an economy weakened by the COVID-19 pandemic and offer solutions to help strengthen systems that are vital to the country, such as infrastructure and transportation.

In this year’s annual report on university research and development, Composites Manufacturing magazine highlights five potentially ground-breaking innovations, from new manufacturing processes to novel materials.

While the lightweighting advantages of multi-material components are attractive to many industries, such as automotive, there are significant challenges to their use. Mixing materials typically necessitates additional manufacturing processes and joining techniques, which hike up the costs for components. Researchers in the Clemson Composites Center think they have a solution with their single-shot manufacturing process for dissimilar materials.

“Most current technologies use multi-stage manufacturing processes,” says Saeed Farahani, a postdoctoral fellow in Clemson’s Department of Automotive Engineering. “You need to first form the metal in a stamping process, then insert it in an overmolding process. Or, you can laminate a sheet metal with a layer of polymer, then use a cold or hot forming process to form the laminated structure. But these have limitations and challenges.”

Farahani and Srikanth Pilla, Jenkins Endowed Professor in the Department of Automotive Engineering, developed a process they call hybrid single-shot manufacturing, which integrates manufacturing of metals and composites in one piece of equipment using a single tooling system. The researchers opted to use injection molding equipment for the technique because it’s readily available in industrial manufacturing settings.

“The general idea behind the integration is to use the pressure of the melt during the injection to form the sheet metal,” says Farahani. “Then, the polymer is injected onto the sheet metal, and the two materials are bonded during the solidification.” Another option is to pre-form the sheet metal while the mold is closing, then inject the polymer after it is closed to make the final formation.

The first materials that Farahani and Pilla tested a few years ago were aluminum and a simple polypropylene. Next, they moved to advanced steel. They have also tested several composite materials, including carbon fiber prepreg sheets with epoxy resin. “In that case, we manufactured a hybrid thermoset/thermoplastic structure in a single shot,” says Farahani. “From the composite standpoint, as long as you can put the material inside the injection molding equipment, we can make it work.”

The researchers faced several challenges along the way. The first was related to modeling and simulation for the process, which is a combination of sheet metal forming and injection molding. Existing software for sheet metal forming processes can’t model the flow of the polymer, while packages for injection molding processes can’t account for deformation of components. “We had to develop custom models for our process and, based on those models, create our own simulation tools to better understand the process,” says Farahani.

The team has also addressed tactical challenges for potential industrial applications, such as the opposing phenomena of “spring back” in metals during the deformation process and shrinkage of materials during injection molding. Farahani and Pilla developed a patent-pending method to prevent the ensuing delamination and debonding. They also have integrated sensors in the tooling and utilized advanced modeling and artificial intelligence to better control the process and monitor the final quality of the hybrid component.

“We now believe this process is mature enough to be implemented in industrial applications,” says Farahani. He adds that hybrid single-shot manufacturing can not only reduce the aforementioned difficulties and limitations in manufacturing multi-material structures, but also opens up new opportunities to cost-effectively produce multi-functional, smart components. The added functionality can be diverse, and the emerging applications can go beyond automotive, including aerospace, consumer markets, biomedical and construction.

“We foresee applications in any domain where there is a necessity for complex geometries with diverse functionalities,” says Pilla.

CNT Curing for Aerospace Parts

Project: Carbon nanotube porous networks

School: Massachusetts Institute of Technology

Location: Boston

Principal Investigator: Brian L. Wardle

More than a decade ago, researchers at MIT and Metis Design were testing sensors made with carbon nanotube

(CNT) networks under funding from the Air Force Office of Scientific Research when they noticed something interesting. Depending on how they were measured, the CNT heated up.

This tangential discovery led the researchers to investigate CNT films as lightweight resistive heaters, which the Naval Air Systems Command (NAVAIR) funded to develop into an embedded deicing system for aircraft.

During that project, Brian L. Wardle, professor of aeronautics and astronautics at MIT, says the team realized the technology might work for curing: “We’re placing a heater on this aerostructure for ice protection. Why don’t we use that heat to actually cure the part underneath in the first place? It sure gets plenty hot.” Fast forward to today and that is exactly what MIT and Metis Design are doing on behalf of NAVAIR – developing a CNT-based conductive heating technique that, when combined with carbon nanoporous network (NPN) film, can be used to manufacture aerospace-grade composite materials.

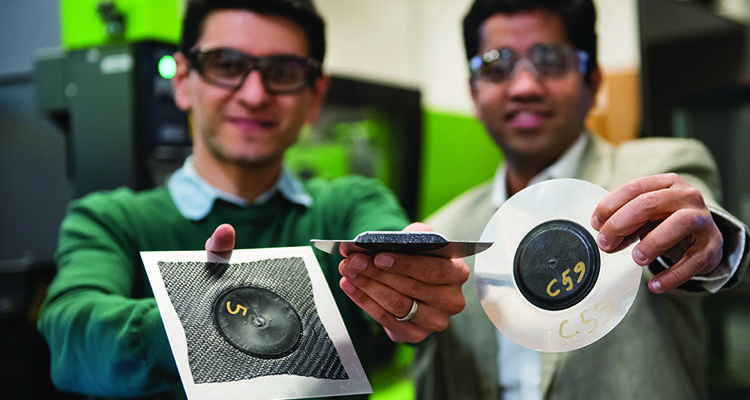

To begin, the team developed an out-of-oven (OoO) process that uses carbon nanotube film to heat and cure out-of-autoclave prepreg materials. In the early years, MIT grew vertically aligned carbon nanotubes and “knocked them down” to create the horizontally aligned CNTs this process requires. Now, they are commercially purchased in large format sheets. Researchers then created a NPN that provides capillary pressure to enable curing traditional autoclave-required graphite epoxy prepreg materials. The NPN film is made of 8-nanometer diameter, multi-walled, vertically aligned carbon nanotubes that are grown at MIT. While the largest part cured so far is a x 30-centimeter flat panel, Estelle Cohen, lead researcher for the collaboration at Metis Design, plans to make a 60 x 60-centimeter flat panel and a curved part by the fall, with customers talking about scaling to much larger and complex parts early next year.

The technique has many advantages. Foremost are reduced energy costs. This resistive heating technique uses just 1% of the energy that would be required to cure large composite parts in an autoclave. “That’s a step change in energy efficiency,” says Jeonyoon Lee, a postdoctoral researcher leading the project at MIT.

The process is also faster. Seth Kessler, president of Metis Design, says that because CNTs heat more rapidly and uniformly than an oven or autoclave, the technique can be used to cure parts in roughly half the time. Most recently, the team documented a 90-minute reduction in cure time, which is good news for throughput. “That’s going to translate into making more parts per hour, per day, which is obviously going to translate into increased margins,” says Kessler.

CNT-based resistive curing could significantly reduce barriers to entry for companies that can’t afford an autoclave. “All you need is enough shop floor space for the tool,” says Kessler. “That means that any medium or even small-sized business that can afford to get a warehouse would possibly be able to make large composite parts. This technology really has the opportunity to revolutionize the way that composites enter non-traditional markets.”

Tools will also be far cheaper – perhaps a fraction of the cost of a traditional mold – spurring further market entry and faster innovation. “Right now it is very difficult to iteratively design and test composite parts, especially after production begins because traditional molds can cost millions of dollar, take six months to fabricate and can be virtually impossible – or at least financially impractical – to re-work,” Kessler explains. “Pressure-free curing outside of an autoclave allows you to rapidly prototype parts and go through design iterations much more easily.”

Wardle sums up the benefits: “A lot of parts are bottlenecked by the autoclave process. This technique absolutely gets you to a lighter infrastructure and much lighter, flexible and robust manufacturing processes.”

Healing Broken Bones with CFRP

Project: Braided carbon fiber tubes and polymer cement

School: The University of Arizona

Location: Tucson, Ariz.

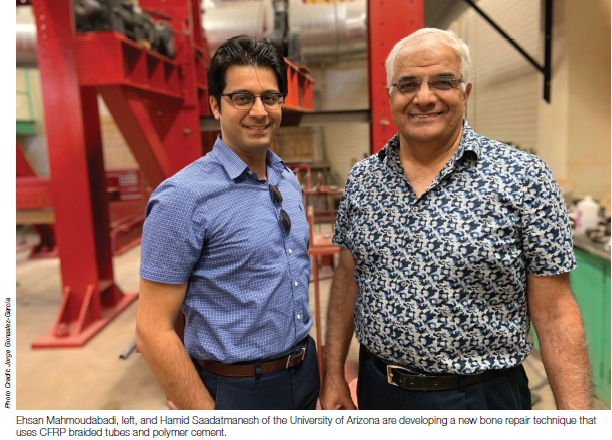

Principal Investigators: Hamid Saadatmanesh and Ehsan Mahmoudabadi

Structural engineers at the University of Arizona are adapting a CFRP process used to reinforce ailing infrastructure columns to repair broken bones. “When supporting a structure – whether it is a bridge or the body of a person – the mechanics are more or less the same,” says Hamid Saadatmanesh, professor of structural engineering.

Saadatmanesh, who has focused on composite-reinforced infrastructure projects for decades, hadn’t considered biomedical applications until a cardiologist asked him to examine the viability of CFRP heart valves. That sparked another idea: “It came to me that we could make a direct transfer from this proven civil engineering technique that has worked well for bridges and convert the technology for use in the human body,” he says.

To repair degraded concrete and steel supports on bridges, piers and highways, a braided CFRP tube is inserted into the hollow column and filled with polymer concrete, creating a new structural column inside the existing form. Saadatmanesh believes surgeons could stabilize broken bones in the same way, by aligning broken bones, inserting a braided CFRP tube into the bone cavity and filling it with bio-compatible polymer. As the polymer fills the CFRP sleeve, it would expand and take the form of the bone’s cavity. “The whole system works like steel-reinforced concrete,” says Ehsan Mahmoudabadi, professor of structural engineering. “But here we have carbon fiber as the tensile material and polymer concrete as the compression part.”