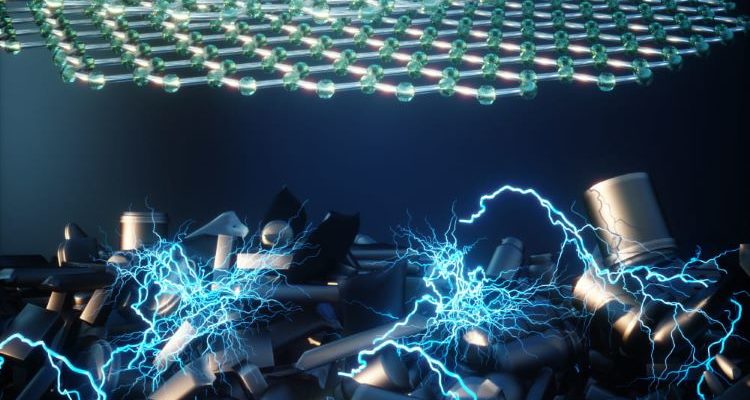

A new process introduced at Rice University can turn bulk quantities of just about any carbon source into valuable graphene flakes using a burst of heat and light. Bulk composites of graphene with plastic, metals, plywood, concrete and other building materials would be a major market for flash graphene.

Flash graphene is made in 10 milliseconds by heating carbon-containing materials to 3,000 Kelvin (about 5,000 degrees Fahrenheit). The source material can be almost anything with carbon content including food waste, plastic waste, petroleum coke, coal, and wood clippings. According to James Tour, a chemist at Rice University, the flash graphene technique can convert these materials into graphene for a fraction of the cost used by other bulk graphene-producing methods.

“This is a big deal,” Tour said. “The world throws out 30% to 40% of all food, because it goes bad, and plastic waste is of worldwide concern. We’ve already proven that any solid carbon-based matter, including mixed plastic waste and rubber tires, can be turned into graphene.”