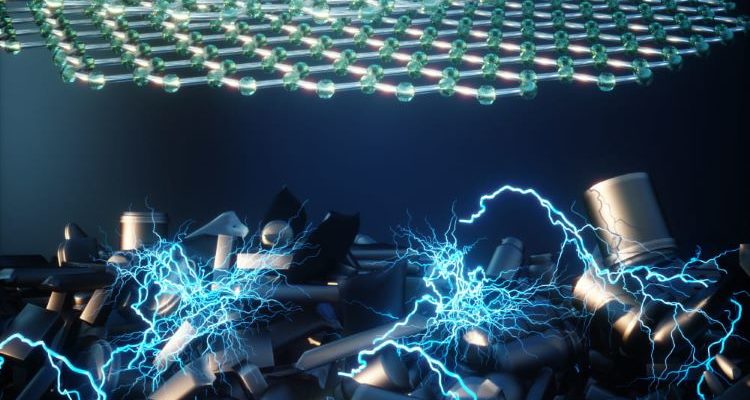

The process produces turbostratic graphene with misaligned layers that are easy to separate. “A-B stacked graphene from other processes, like exfoliation of graphite, is very hard to pull apart,” Tour said. “The layers adhere strongly together. But turbostratic graphene is much easier to work with because the adhesion between layers is much lower. They just come apart in solution or upon blending in composites.” Tour continued, “That’s important, because now we can get each of these single-atomic layers to interact with a host composite.”

Temperature is the key to success in the flash process which occurs in a custom-designed reactor that heats material quickly and produces very little excess heat. No solvents are used, keeping the process very clean. Rice researcher Ksenia Bets said, “We essentially speed up the slow geological process by which carbon evolves into its ground state, graphite. Greatly accelerated by a heat spike, it is also stopped at the right instant, at the graphene stage.”

The researchers are already testing graphene-enhanced concrete and plastic. In the past, Tour said, “graphene has been too expensive to use in these applications. The flash process will greatly lessen the price while it helps us better manage waste.”