When designing the battery enclosure, “we need to be very aware of the parts count and the job each component is doing. When you approach this with the whole picture in mind, you get to choose where you want those joints, where they are least exposed and where they add more value,” he says.

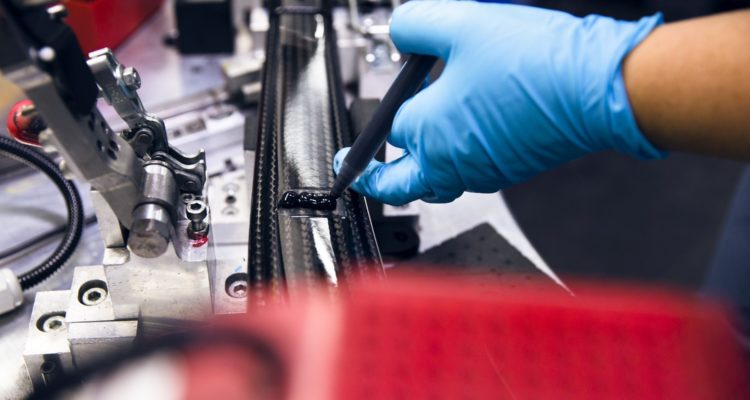

In most cases, Katcon uses both mechanical connections and adhesives in the joints. Although mechanical fastenings add some complexity, Armendariz doesn’t expect that the industry will switch entirely to an adhesive solution anytime soon.

“It’s not just about lightweighting; it’s also being efficient with material allocations, energy utilization and the need to be sustainable. So, the optimal combination is when we use adhesives in combination with other joining methods,” he explains.

In the future, Armendariz expects to see greater use of multi-material components throughout vehicles. “In the end, I think that’s going to help us design better vehicles, grow efficiencies and be more sustainable,” he says.

Better Solutions for Bonding

In 2014, researchers working on a composites technology roadmap for the National Institute of Standards and Technology questioned manufacturers about the areas of research they were most interested in. Finding the best way to join composites with other materials was one of their top three concerns. Established in July 2021 at the Georgia Tech Manufacturing Institute, the Center for Composite and Hybrid Materials Interfacing (CHMI) will research this topic through a five-year, renewable grant from the National Science Foundation’s (NSF) Industry-University Cooperative Research Center (IUCRC) program.

The three universities involved – Georgia Tech, Oakland University in Michigan (OU) and the University of Tennessee, Knoxville (UTK) – will collaborate with members of an industry consortium to develop and disseminate methods, technologies and tools that facilitate rapid, reliable and cost-effective composite and hybrid materials joining and interfacing. CHMI’s goal over the next 10 years is to reduce, by at least 50%, the cost, cycle time and variation of these operations.

Industry input is built into the project. Consortium members vote on which projects to pursue, and they fund the research through their membership fees. In addition, company representatives will serve as mentors to review progress and guide the project research. Each university has a different industry focus – Georgia Tech on aerospace, OU on automotive and UTK on infrastructure and medical devices.

In aerospace, the push for lighter weight aircraft has increased the need for better composites and multi-material joining solutions, says Chuck Zhang, CHMI’s director and the Harold Smalley Professor in Georgia Tech’s H. Milton Stewart School of Industrial and Systems Engineering. Airlines know how to repair and maintain older, mostly metal aircraft like the 737 and 757. But they lack the expertise required for the newer Boeing 787 and Airbus A350, in which more than half of the structure by volume is composite materials. Many of these repairs involve aircraft sections where composite components are used in conjunction with components manufactured from other materials.

“People in the aircraft maintenance field tell me that they have very limited knowledge of how to repair these. If there’s minor damage, they can patch it, but if there’s major damage – like a big hole in the wing or fuselage – they normally have to go back to the OEMs,” Zhang says. That can quickly drive up the airline’s repair and maintenance costs.

Manufacturers of these aircraft have their own concerns about multi-material components. For example, when they drill holes and use mechanical fasteners to join composite materials with aluminum or steel, the composite materials may get damaged and lose strength.

Zhang says that CHMI researchers originally thought their focus would be on creating advanced adhesives that would eliminate the need for mechanical fasteners. But the airline industry representatives pointed out that the FAA requires both adhesive and mechanical fastening for multi-material joints. So, one area that CHMI research teams could focus on is developing computational models, process control and non-destructive testing methods that could help change those requirements. They might test adhesives and processes on a repair for subscale, such as a 3 x 3-foot composite/metal structure, and then use modeling to predict how feasible this solution would be on a larger scale.

CMHI researchers and their industry partners also hope to find ways to increase automation of the composite/metal joining process during both manufacturing and repair. This will be easier to achieve in the manufacturing plant, where work can be standardized, than in the field, where repairs to a composite or multi-material aircraft may be required in many places.

For instance, the researchers might study robots like those developed by Lufthansa Technik as part of its CAIRE Project (Composite Adaptable Inspection and Repair). The mobile robots can cling to aircraft wings and fuselages to inspect and repair the composite structures by scanning and recording damages, removing damaged materials and producing customized repair layers, says Zhang.

The creation of CHMI comes at a good time for the composites industry. As demand for multi-material solutions continues to grow, manufacturers will need to find ways to ensure that customers who choose mixed material solutions will benefit from the desirable properties that each material offers.

Mary Lou Jay is a freelance writer based in Timonium, Md. Email comments to mljay@comcast.net.