The strength, durability and light weight of composites have made them the material of choice for many applications in aerospace, automotive and other industries. But composites can’t always provide all the properties that customers need for specific applications. Combining them with steel, aluminum or other materials often yields the ideal solution.

Creative Composites Group’s (CCG) GFRP rail platforms and bridge decks are installed throughout the U.S. But when it came to joining the different sections together, the company realized that they needed metal reinforcement to form a secure connection. A bolt put into a composite part will pull out at a lower load than a bolt put into a steel part.

Years ago, CCG started embedding carbon steel plates along the edges of GFRP panels during the vacuum infusion process, using a primer on the steel to strengthen its chemical adherence to the resin. Threaded bolt holes are then drilled in the GFRP/steel edge. Installation crews use external hardware to attach the FRP panels to support the structure and join the FRP sections together in the field, then seal the hole with caulk to try to prevent water intrusion.

However, since water tends to seep in despite these precautions, CCG switched from carbon steel to stainless steel for the reinforcement plates. “Composites are generally at a premium price over steel or concrete, and part of the value that we’re selling is longevity,” says Scott Reeve, business development for CCG. “You want to have the steel on the inside of a product to be a type that’s going to last as long as the FRP.”

The company also embeds steel into composite components that require added stiffness, such as extended cantilevered structures. “The basic structure is composites, which keeps the weight down and keeps the corrosion resistance, but there are steel channels totally encapsulated in the FRP. It’s the most economical use of the two materials,” says Reeve.

In the past, CCG has also used thin steel strands instead of glass or carbon fibers when manufacturing FRP components for certain applications. This provides added stiffness while reducing thickness, since fewer layers of the steel-fiber-reinforced composite are required. The drawback to this material is that the steel fibers provide reinforcement only in one direction; they don’t have the multi-directional properties of composites reinforced with other types of fiber.

Reeve says that owners of vehicle bridges with composite railings often request that steel reinforcements be placed inside railings. If a vehicle hits the structure, bridge owners are more comfortable knowing that the load from the impact will be transferred to the steel – a material they’re familiar with – rather than to the composites, which they may not know as well. Although engineers are growing more knowledgeable about composites, the multi-material approach provides extra reassurance, adding the longevity of composites with the known strength of steel.

Finding the Right Combination

In the automotive industry, companies like SGL Carbon and Katcon are designing and producing multi-material battery enclosures for electric vehicles (EVs).

One of SGL’s first projects was the development and prototype production of the battery case for the NIO electric smart car. The materials included extruded aluminum for the side rails, composites for the top and bottom plates, and steel for the mounting parts. The combination was chosen to meet weight targets, performance requirements and crash behavior.

“In general, in the field of battery enclosures, metallic parts are used for the load introduction as well as for crush zones, while the composite overtakes the load distribution,” says Dan Gillig, SGL’s North American technical sales manager.

When developing a mixed material component, SGL considers not only the process of combining the different materials but also how to prevent problems like galvanic corrosion during the vehicle’s lifetime. The design takes into account the different materials’ properties, how they react to specific forces and the load transfer/distribution between parts.

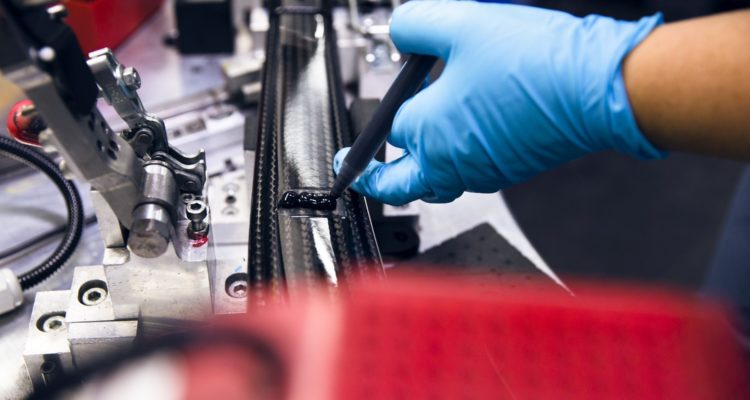

SGL varies its joining technologies according to the materials used and the specific part’s function. Liquid adhesive technology, for example, is important not only to attach the parts to each other but also to carry loads and avoid the creation of weak spots in the assembly. Some assemblies are supported by bolting or riveting, which provides a local mechanical connection in an area where adhesive bonding is carrying the load transfer. Inserts directly integrated into the composite structure or easily bonded threaded studs are often used for mounting points in the assembly when lower loads are being transferred.

Katcon, based in Santa Catarina, Mexico, has worked with Forward Engineering in Munich, Germany, to develop a toolbox of materials, processes and design knowledge that’s intended to help manufacturers achieve the best configuration for their specific battery electric vehicle (BEV) platforms. “The goal is to have a lighter battery enclosure that is also economically feasible, safe and sustainable and that can be mass produced,” says Juan Armendariz, Katcon’s general manager.

“We found that steel and composites make a great combination,” he says. “We use the steel in the structural members. We use the composites for large panels that are typically expensive to produce in steel due to machinery, tooling and the associated capital expenditures. We can produce those parts more effectively with composites, and the composites are very well suited for intrusion resistance and fire resistance.”

Steel is a good choice in combination with composites because it is cost effective for large-scale production, has excellent fire-resistance and OEMs are already familiar with it, adds Armendariz.